Brand:

TOB NEW ENERGYitem no.:

TOB-JS400-4order(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMENSingle Side Slot Die Coating Machine For Lab

SPECIFICATIONS

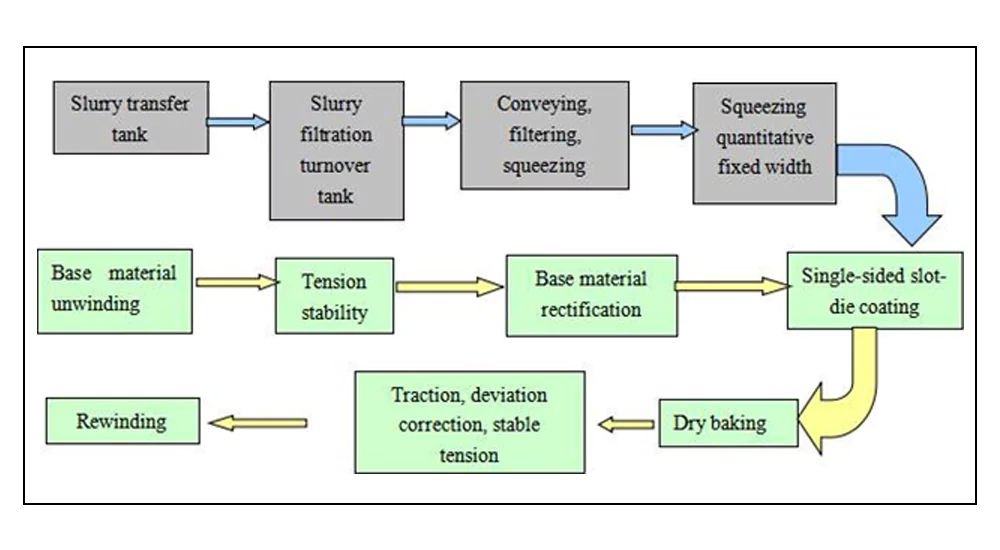

Equipment Functions and Principles

This single side slot die coating machineis used for precision coating of cathode and anode electrode of lithium-ion batteries. It mainly consists of unwinding part, machine head part, oven part, traction part, winding part, and electric control part. Evenly coat the stirred slurry onto the substrate, ensuring that the size, weight, etc. are within the process range. After drying treatment, roll it up and prepare for the subsequent process.

Base material parameters

|

Item |

Cathode |

Anode |

|

Base material |

Al foil |

Cu foil |

|

Width(mm) |

160~320 |

160-320 |

|

Thickness(µm) |

8~15 |

6~12 |

Slurry parameters

|

Item |

Cathode |

Anode |

Tab glue |

|

Material |

LFP, NMC ,etc |

Graphite |

Al2O3、boehmite |

|

Solvent |

NMP |

DI-Water |

NMP |

|

Solids(wt%) |

52~65(LFP) 60~76(NMC) |

42~50 |

30~40% |

|

Specific gravity of slurry(g/cm3) |

1.5~2.5 |

1.0~2.0 |

- |

|

Viscosity(mPa.s) |

3500~12000 |

2500~8000 |

1000~3000 |

|

Remark: 1) Solid content of the same batch of slurry: fluctuation ≤ ±0.5%. 2) The viscosity of the same batch of slurry: fluctuation ≤ ± 500mPa. s, any temperature fluctuation within the 22-30 range ± 2℃. 3) During acceptance, one type of cathode slurry; one type of anodeslurry. |

|||

Coating parameters

|

Item |

Cathode |

Anode |

|

Coating mode |

Continuous, Intermittent, Stripe coating |

Continuous, Intermittent, Stripe coating |

|

Coating width(mm) |

150-300 |

150-300 |

|

Dry thickness of single-sided coating(µm) |

70~350 |

60~350 |

|

Single coating weight (g/㎡) |

30~250 |

20~200 |

|

Coating speed(m/min) |

0.5~1 |

0.5~1.5 |

Explanation: The coating speed is related to product characteristics (material system, coating thickness, solid content, temperature), and the maximum coating speed given in the table cannot meet special coating process requirements.

Equipment specifications and parameters

|

No |

Item |

Content |

|

1. |

Roll surface width |

400mm |

|

2. |

Mechanical speed (unloaded) |

Max.5m/min |

|

3. |

Unwinding specifications |

Roll diameter: Max φ 300mm;Load bearing: Max.100kg. Roll specification: inner diameter of 3 inches, approximately 76.2mm, length of 400 ± 3mm Roll material: metal, ABS plastic |

|

4. |

Winding specifications |

Roll diameter: Max φ 300mm;Load bearing: Max.100kg. Roll specification: inner diameter of 3 inches, approximately 76.2mm, length of 400 ± 3mm Roll material: metal, ABS plastic |

|

5. |

Oven heating method |

Electrical heating |

|

6. |

Oven structure |

1 section×2m/section=2m,single layer |

|

7. |

Oven temperature |

Max.150℃ |

Main components of the equipment

|

Name |

QTY |

Remark |

|

Unwinding unit |

1set |

Single station, automatic unwinding, manual roll changing |

|

Coating unit |

1set |

/ |

|

Coating feeding unit |

1set |

Including mixing drum, pump, filter, valve, etc |

|

Oven unit |

1set |

Single layer,1 section×2m=2m |

|

Traction unit |

1set |

/ |

|

Winding unit |

1set |

Single station, automatic unwinding, manual roll changing; |

|

Controller |

1set |

/ |

Optional Function

| Edge Coating | (1) The positive electrode is equipped with edge gluing mechanism, screw pump + dispensing head gluing mode, gluing parameters are as follows: |

| (2) Coating glue width: 3-10mm±1mm | |

| (3) Coating glue thickness: 30-70um±15um single-side dry thickness | |

| (4) Slurry requirements: filter more than 150 mesh, viscosity 1500±300PCS, solid content 40%±5% | |

| (5) Covering area: 0.2~1.0mm (no metal leakage, no drum edge) | |

| (6) Gluing feeding system: barrel volume 10L, single-core capsule filter installed in an independent trolley Number of adhesive strips: 1 to 4 | |

| NMP Solvent Concentration Alarm | (1) The second section of the positive electrode box is equipped with an NMP concentration alarm device, a total of 1 set, and installation positions are reserved for the remaining sections. |

| (2) When the concentration exceeds 35%, the equipment should give an audible and visual alarm. | |

| (3) When the concentration exceeds 50%, the equipment automatically stops running, and the exhaust fan automatically operates at maximum frequency. | |

| (4) Anode not configured, reserved installation interface. |

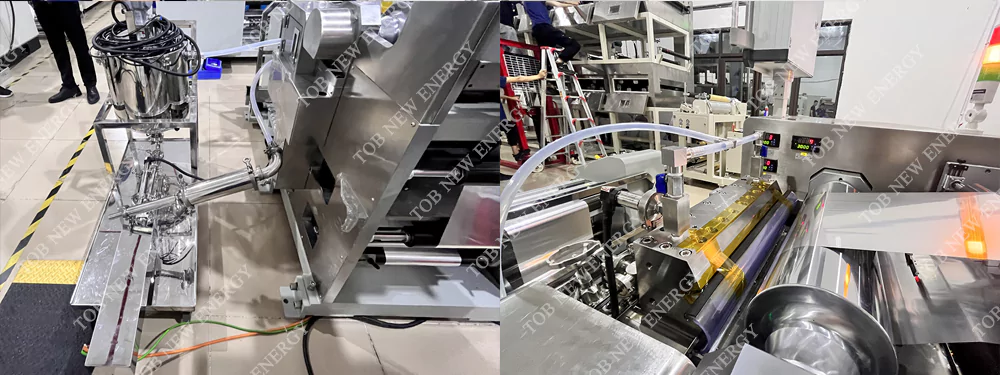

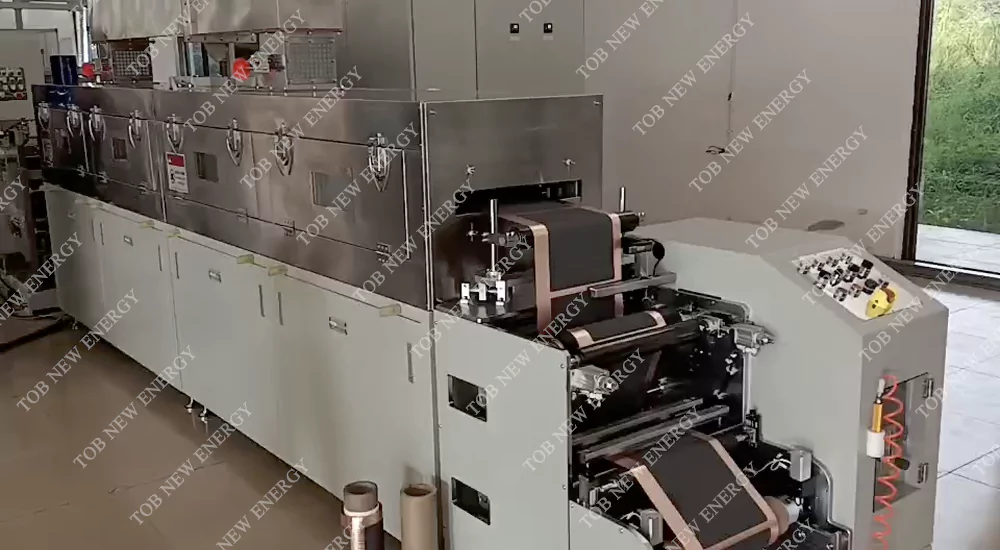

PRODUCT DISPLAY

TOB-JS400-2 Roll to Roll Coating Model

Skype : amywangbest86

Whatsapp/Phone number : +86 181 2071 5609

Previous:

Battery Electrode Continuous Scraper Coating MachineNext:

Single Side Slot Die Battery Coating Machine For LabIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.