Brand:

TOB NEW ENERGYitem no.:

TOB-3013-2order(moq):

1Payment:

L/C,T/Tproduct origin:

Chinashipping port:

xiamenLead Time:

30 days

SPECIFICATIONS

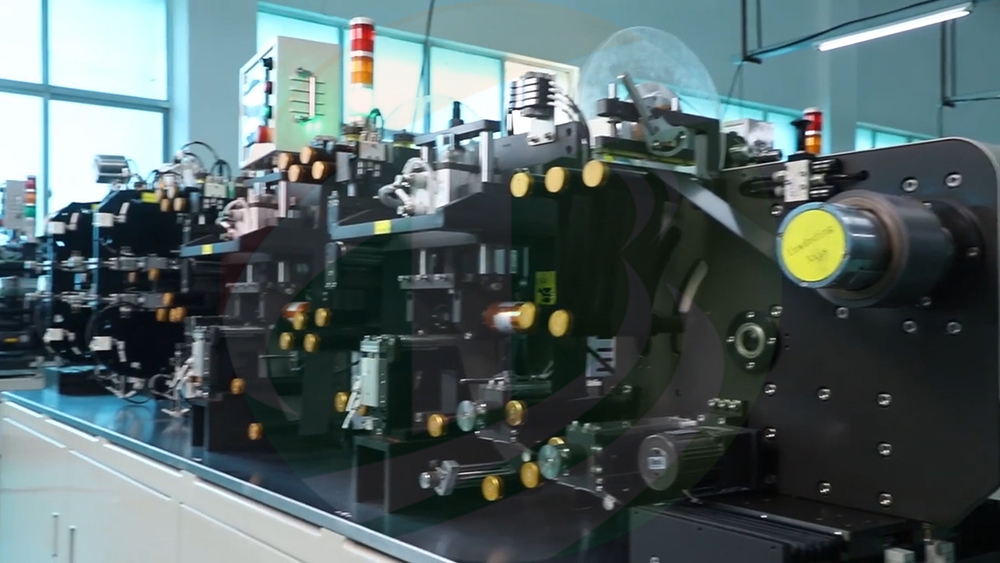

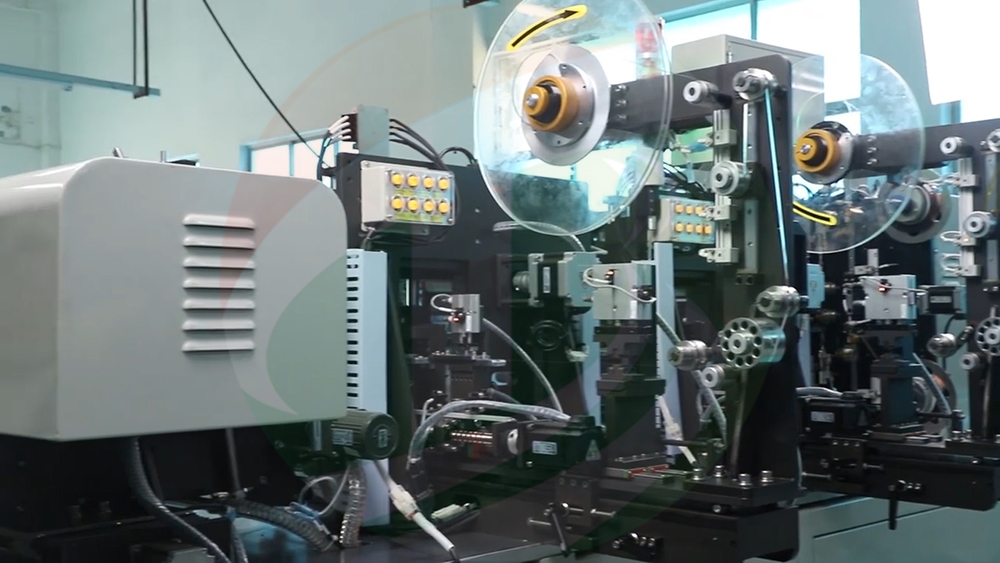

Contact us for more information about this automatic battery electrode making machine ( tab welding, adhesive tape sticking ).

This equipment is a special production equipment for the production of lithium ion batteries .

1.Slitted roll electrode is hung on the unwinding shaft of the equipment, after the tension control, material discharge deviation correction, the over-electrode roller is sent to the tab welding (ultrasonic welding) part for the tab welding, traction to the set position, automatic paste two, after the dust suction device, traction mechanism, the finished single piece of the electrode, automatic wind of the whole roll.

2.The selection of the reference point is to use the starting point of coating on the electrode as the dividing line for positioning, as the reference point of tab welding;The intermediate process of the equipment is the detection of whether the tab is welded, the detection of whether the tape is affixed, etc.Once found that there is no welding or no adhesive tape, you can manually push the switch to return the electrode traction, repair welding, subsidies.make whole roll electrode automatically overwelds the upper tab, automatically sends the electrode, after sticks the protective tape on the electrode and the tab, and automatically harvests the whole roll the finished electrode.

| Item | Requirement | Instructions | Remark |

| Electrode size | Thickness 90um-250um. Width 40mm-130mm | No wrinkle and wavy edge through the roller of the electrode. | |

| Single electrode length | 300 mm-2000 mm | ||

| Tab width | 3、4、5、6mm | ||

| Protective tape width | 6-20 | Width adjustable | A group of stick |

| Length of stick glue | 40mm-80mm | ||

| Tab length | 30 mm-80mm | ||

| tab exposed length | 10 mm-25mm | tab plastic bags | |

| Position accuracy of tab tape | ±0.5mm | ||

| tab protection tape length position accuracy | ±0.5mm,Two protective glue sticking mechanisms | ||

| Length error of tab welding | ±0.5 mm,no warping deformation in the tab, and the end burrs are cut≤0.01mm.Cutter effective life≥1million times | ||

| Welding position error of tab | ±0.5mm,Effective welding area≥80%,Welding tension≥15N,No overwelding and virtual welding, effective life of welding head and welding seat≥1million times | A group of welding institutions | |

| Welding skewness of tab | ±2° | ||

| Wind function | Alignment accuracy ± 1mm, with anti-explosion edge of the rolling mechanism | ||

| Speed | 1 tab welding once, the speed is about ≥20PCS / min | Within 1700mm | Post once |

| Product pass rate | ≥97% | ||

| Utilization rate | ≥94% | ||

| Ultrasonic welding standard | China | Kepu | |

| Servo Control | Delta | ||

| electrode film brushing method | When rewinding the roller, it is equipped with a brush and dust collection device and sucks away |

PRODUCT DISPLAY

Whatsapp/Phone number :+86 181 2071 5609

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.