Brand:

TOB NEW ENERGYitem no.:

TOB-GH3000-1order(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMENUltrasonic Metal Rolling Welding Machine

SPECIFICATIONS

This ultrasonic metal rolling welding machine is efficient, precise and clean. Its biggest feature is the continuous emission of ultrasonic waves, which can be rolled welding.

Introduction

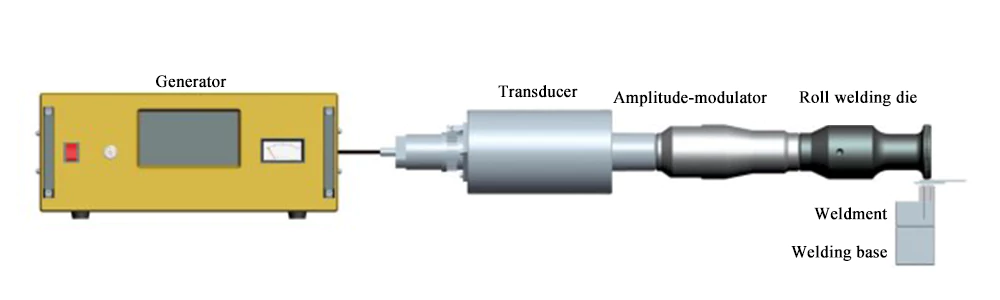

Ultrasonic welding is a solid-state welding method, in which the connection between the welded parts is achieved through high-frequency elastic vibration of an acoustic system and the clamping effect of static pressure between the workpieces. The ultrasonic generator is a frequency conversion device that changes the power frequency current into an oscillating current at the ultrasonic frequency, while the transducer relies on the "piezoelectric effect" to convert the ultrasonic frequency electrical energy fed into the generator into mechanical vibration energy. An amplifier is used to amplify the amplitude and couple the load. Welders convert the energy into frictional energy, deformation energy, and thermal energy between workpieces under the combined action of static pressure and elastic vibration energy, resulting in the formation of a surface oxide film on the surfaces of the two workpieces, thus achieving friction welding. When different metal materials are welded, mixed molecular interfaces are formed, resulting in metallurgical welding.

Principle

The transducer converts electrical energy into mechanical energy of the corresponding frequency, which is applied to the interface of the metal sheet to be welded. This instantly generates heat at the junction of the metal sheet, activating the molecules in the metal lattice and causing the atoms at the junction of the metal sheet to penetrate and weld together.

Procedure

|

No. |

Material |

Welding method |

Process application |

|

1 |

Aluminium(0.8-1.8mm) |

Rolling welding |

Aluminum tube |

Basic parameters

Equipment composition (quantity per unit)

|

No. |

Name |

QTY |

Remark |

|

Ultrasonic head |

1 pcs |

3000W |

|

|

The ultrasonic generator |

1 pcs |

20KHZ |

|

|

Industrial control generator |

1 pcs |

220V |

|

|

Ultrasonic transducer |

1 pcs |

20KHZ |

Basic parameters

|

No |

Name |

Parameters |

Remark |

|

1 |

Configure power supply |

Single-phase power supply,220VAC±10%,50Hz |

|

|

2 |

Compressed air demand and pressure |

0.6m³/min |

|

|

3 |

Environmental requirements |

humidity﹤48%。 |

|

|

4 |

Welding parameters |

Rolling continuous ultrasound |

|

|

5 |

Adjustable amplitude |

10-95% adjust |

|

|

6 |

Equipment frequency |

Equipment frequency:20KHZ±100Hz(automatic tracking) |

|

|

7 |

Electric power parameters |

Input maximum electrical power:3000W(Adjustable power) |

|

|

8 |

Welding mode |

Continuous mode |

|

|

9 |

Equipment control mode |

The manual motor is controlled by a foot switch signal. |

|

|

10 |

Speed |

≧8-10m/min |

|

|

No. |

Item |

Technical Parameter |

Remark |

|

1. |

Ultrasonic head |

20KHz,According to the processing diagram |

|

|

2. |

The ultrasonic generator |

20KHz |

|

|

3. |

Industrial control generator |

Can be adjusted for speed |

|

|

4. |

Ultrasonic transducer |

20KHz,width 3mm |

|

Main component brands

|

No. |

Name |

Brand |

Country |

|

1 |

Pneumatic part |

New Lide |

TaiWan,China |

|

2 |

Head frame |

|

China |

|

3 |

Ultrasonic transducer |

|

China |

|

4 |

Displacement sensor |

NOVOTEChNIK |

Germany |

|

5 |

Electronic proportional valve |

NOVOTEChNIK |

Germany |

|

6 |

Ultrasonic amplitude rod |

|

China |

|

7 |

Ultrasonic transducer |

|

China |

|

8 |

Transmitter |

SBT904 AVENTICS |

China |

|

9 |

The ultrasonic generator |

|

China |

List of vulnerable parts and spare parts(Spare parts are randomly given)

|

No. |

Name |

QTY |

Remark |

|

1 |

Ultrasonic transducer |

1 set |

20KHZ |

|

2 |

Adjustable wrench |

1 set |

38-42 |

|

3 |

inner hexagon spanner |

1 set |

|

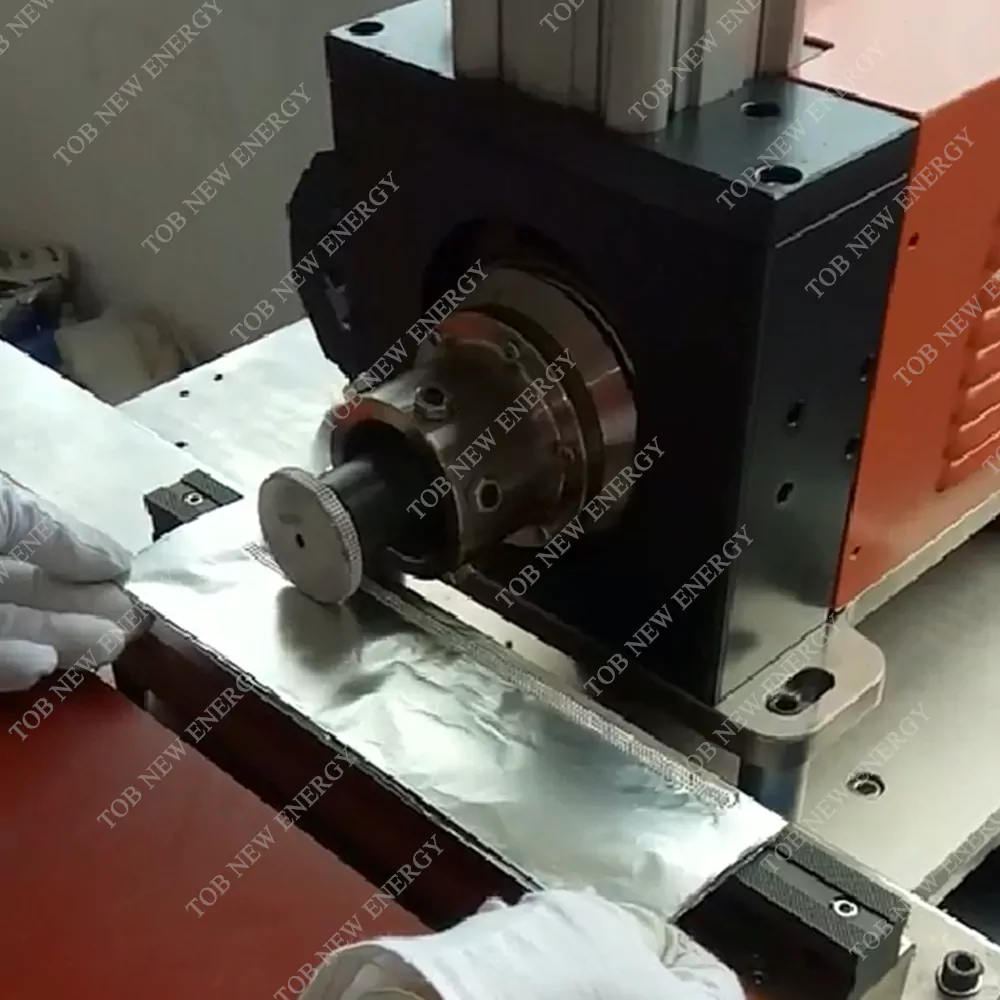

PRODUCT DISPLAY

More battery welding machine for battery research and manufacturinmg

Email: tob.amy@tobmachine.com

Skype:amywangbest86

Whatsapp/Phone number:+86 181 2071 5609

Previous:

Automatic Lithium Battery Cathode Electrode Making MachineNext:

Lab Ultrasonic Battery Spot Welding MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.