Brand:

TOB NEW ENERGYitem no.:

TOB-JS400-1.2Yorder(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMENSingle Side Slot Die Battery Coating Machine For Lab

SPECIFICATIONS

Equipment functions and parameters

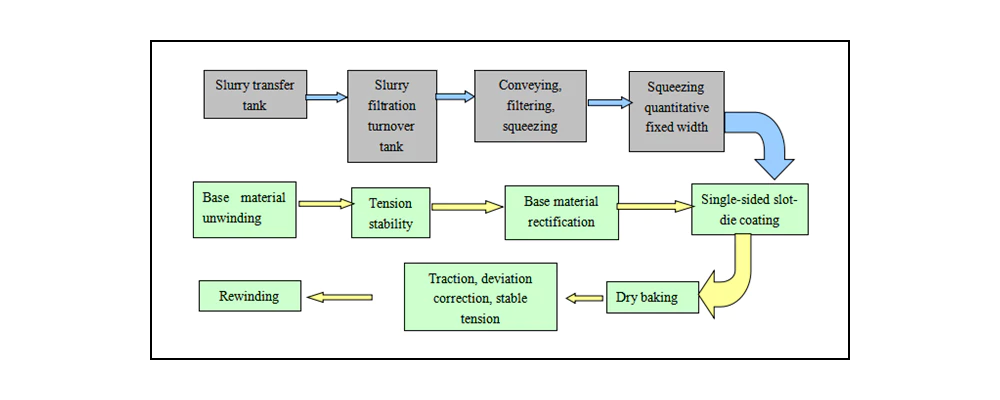

Introduction to Equipment Functions and Principles

This equipment is used for precision coating of cathode and anode electrode of lithium-ion batteries. It mainly consists of unwinding part, machine head part, oven part, traction part, winding part, and electric control part; Evenly coat the stirred slurry onto the substrate, ensuring that the size, weight, etc. are within the process range. After drying treatment, roll it up and prepare for the subsequent process.

|

Item |

Cathode |

Anode |

|

Base material |

Al foil |

Cu foil |

|

Width(mm) |

180~320 |

180-320 |

|

Thickness(µm) |

8~15 |

6~12 |

|

Remark:The base material used for acceptance should not have any looseness, uneven thickness and weight, surface oil stains or other phenomena that affect the performance of the tape and coating. |

||

Slurry parameters

|

Item |

Cathode |

Anode |

|

Material |

LFP, NMC ,etc |

Graphite |

|

Solvent |

NMP |

DI-Water |

|

Solids(wt%) |

52~65(LFP) 60~76(NMC) |

42~50 |

|

Specific gravity of slurry(g/cm3) |

1.5~2.5 |

1.0~2.0 |

|

Viscosity(mPa.s) |

3500~12000 |

2500~8000 |

|

Note: 1) Solid content of the same batch: fluctuation ≤±0.5%; 2) The same batch of slurry viscosity: fluctuation ≤±500mPa.s, 22-30 range of arbitrary temperature fluctuation ±2℃; At the time of acceptance, positive slurry: one; Negative slurry: one; |

||

Coating parameters

|

Item |

Cathode |

Anode |

|

Coating mode |

Continuous, Intermittent, Stripe coating |

Continuous, Intermittent, Stripe coating |

|

Coating width(mm) |

Max 300 |

Max 300 |

|

Dry thickness of single-sided coating(µm) |

70~350 |

60~350 |

|

Single coating weight (g/㎡) |

30~250 |

20~200 |

|

Coating speed(m/min) |

0.1-0.5 |

0.1-0.5 |

|

Explanation: The coating speed is related to product characteristics (material system, coating thickness, solid content, temperature), and the maximum coating speed given in the table cannot meet special coating process requirements; |

||

Equipment specifications and parameters

|

No |

Item |

Content |

|

1. |

Roll surface width |

400mm |

|

2. |

Mechanical speed (unloaded) |

Max.3m/min |

|

3. |

Unwinding specifications |

Roll diameter: Max φ 300mm; Load bearing: Max.100kg; Roll specification: inner diameter of 3 inches, approximately 76.2mm, length of 400 ± 3mm Roll material: metal, ABS plastic |

|

4. |

Winding specifications |

Roll diameter: Max φ 300mm; Load bearing: Max.100kg; Roll specification: inner diameter of 3 inches, approximately 76.2mm, length of 400 ± 3mm Roll material: metal, ABS plastic |

|

5. |

Oven heating method |

Electrical heating |

|

6. |

Oven structure |

1 section×1.2m/section=1.2m,single layer; |

|

7. |

Oven temperature |

Max.140℃ |

|

Name |

QTY |

Remark |

|

Unwinding unit |

1set |

Single station, automatic unwinding, manual roll changing; |

|

Coating unit |

1set |

|

|

Coating feeding unit |

1set |

Including mixing drum, pump, filter, valve, etc |

|

Oven unit |

1set |

Single layer,1 section×1.2m=1.2m; |

|

Traction unit |

1set |

|

|

Winding unit |

1set |

Single station, automatic unwinding, manual roll changing; |

|

Controller |

1set |

|

More details for the coating machine, please send Inquiry to us.

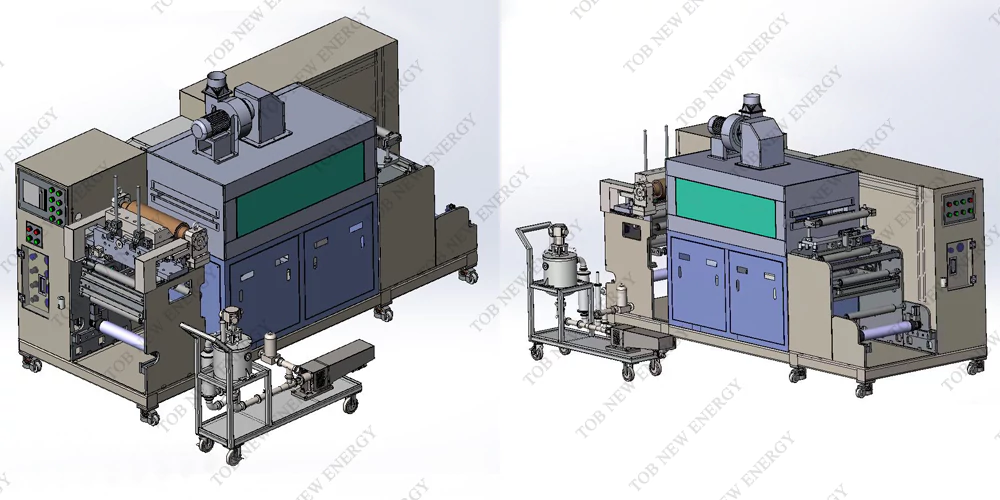

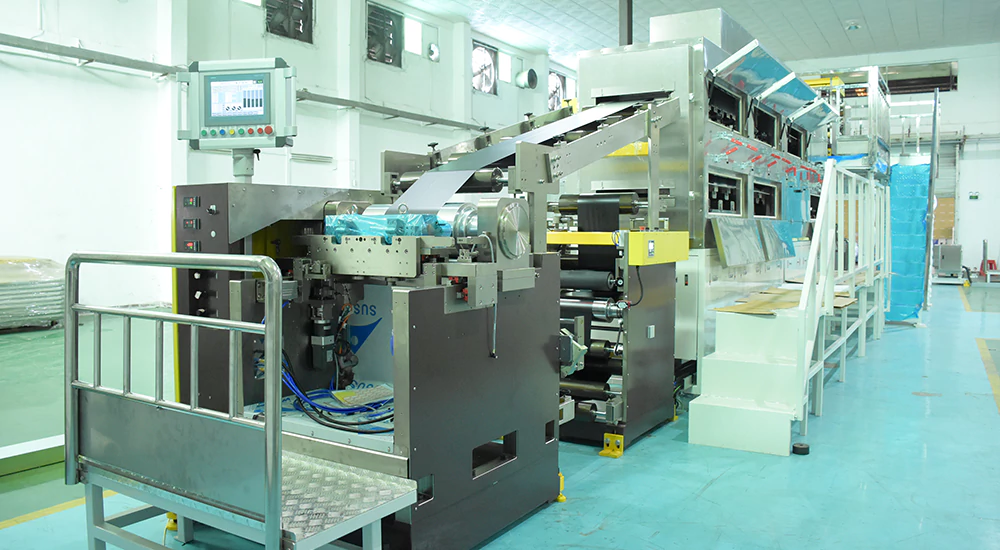

Product Display

More Battery Electrode Coating Machine

Double Side Slot Die Coating Machine

Lab slot die Coating Machine

Single Layer Slot Die Coating machine

1000mm Coating Width Slot Die Coating Machine

Email : tob.amy@tobmachine.com

Skype : amywangbest86

Whatsapp/Phone number : +86 181 2071 5609

Previous:

Single Side Slot Die Coating Machine For LabNext:

Battery Electrode Coating Machine for Battery ManufacturingIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.