Brand:

TOB NEW ENERGYitem no.:

TOB-SY400-3Aorder(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

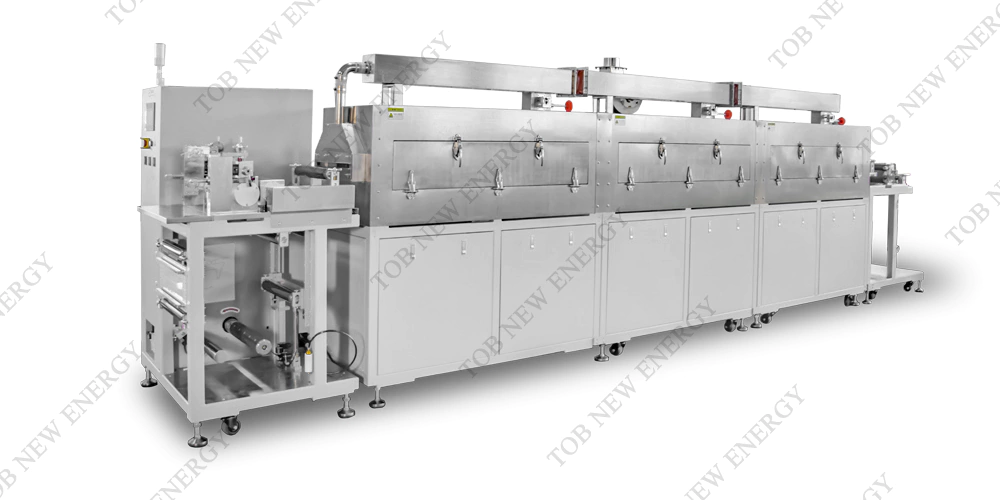

XIAMENBattery Electrode Coating Machine for Battery Manufacturing

SPECIFICATIONS

1. Effective coating width: 330mm.

2. With 3 sections of oven (each section length 1.5 meters), total length 4.5 meters.

3. With automatic gap adjustment function, more easy for adjustment for abroad customers.

4. Perform both continuous and intermittent coating.

This TOB-SY400-3A battery coating machine is a three-roller transfer coating machine, Can perform both continuous and intermittent coating, which is convenient for surface coating of various substrates. Especially applied to the lithium-ion battery industry, the equipment is designed in the spirit of convenience for researchers, while meeting the requirements of coating accuracy and consistency no different from production, with excellent drying effect, ideal for the research and development of lithium-ion batteries, super capacitors, nickel batteries and other secondary batteries.

Features:

* The pushing roller adopts dual servo screw control, which can adjust the finishing coating according to different viscosity slurries.

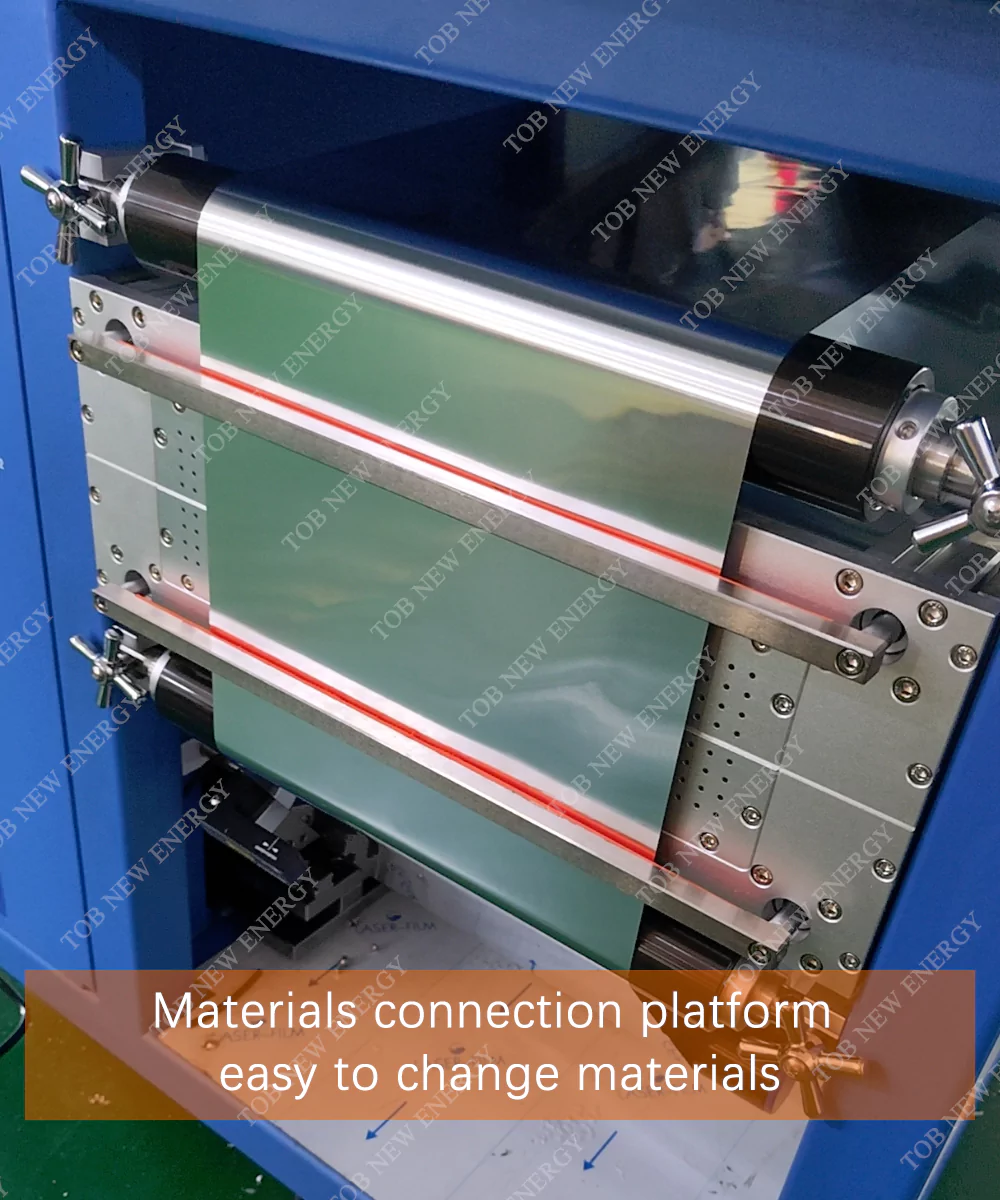

* Equipped with material connecting platform, partition platform, unwinding tension, and dual rewinding tension. Set up correction for unwinding, drying end, and rewinding.

* Freely switchable to achieve continuous and intermittent coating.

* Substrate tension control, stable tape running, equipped with correction device.

* Hot air oven, double-sided blowing on both sides, high-quality drying effect.

* Three roll transfer coating with a wide coating window.

* Measurement with comma scraper, combined with precision adjustment mechanism, achieves high coating accuracy.

* Using analog signals to control power heating, the heating system has high accuracy and long lifespan.

* PLC control, touch screen operation, convenient and easy to use.

Function

|

No. |

Item |

Technical parameters |

Note |

|

1 |

Suitable system |

Coating process for positive and negative electrode sheets of vanadium sodium, lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, graphite, silicon carbon and other system batteries |

|

|

2 |

Coating method |

continuous coating intermittent coating |

Transfer coating |

|

3 |

Adjustment method of scraper roller gap |

Automatic Gap adjustment function by Servo Motor |

Can also choose manual adjust |

|

4 |

Coating speed |

1.5-3meter/min according to baking result |

|

|

5 |

Intermittent coating length |

Coating length 10-5000mm, blank length 10-500mm |

|

|

6 |

Double sided gap alignment |

Photoelectric detection gap automatic tracking head tail gap reverse alignment |

|

|

7 |

Substrate thickness |

Aluminum foil:8~30um Copper foil:8~30um |

|

|

8 |

Roller design width |

400 mm |

|

|

9 |

Coating width |

≤350mm |

|

|

10 |

Coating roller rubber roller |

Φ120mm |

|

|

11 |

Scraper roller |

Φ80mm/Φ100mm |

|

|

12 |

Coating accuracy |

±3um |

|

|

13 |

Coating surface density |

≦±1.5% Containing substrate, excluding abnormal edge areas |

|

|

14 |

Slurry viscosity |

2000~12000 (mPas) |

|

|

15 |

Single-coated dry thickness range |

20-200μm |

|

|

16 |

Solvent characteristics |

Oily solvent NMP(s.g=1.033,b.p=204℃) |

|

|

Watery solvent H2O/NMP(s.g=1.000,b.p=100℃) |

|

||

|

17 |

Suitable solid content |

20~85% |

|

|

18 |

Coating size accuracy (mm) |

Length≤±1 Width≤±0.5 |

|

|

19 |

Positive and negative positional accuracy (mm) |

Length≤±1 Width≤±0.5 |

|

|

20 |

Correction deviation |

±0.3mm |

|

|

21 |

Machine structure |

Head, oven, tail, split type |

|

The structure of each part:

Integrated unwinding, machine head mechanism

|

No |

Item |

Technical parameters |

Note |

|

1 |

Roller installing structure |

Steel frame firmly installed |

|

|

2 |

Roller surface treatment |

Metallic aluminum roller surface oxidation |

|

|

3 |

Tension control system |

Automatic control of constant tension, floating roller sensor control |

|

|

4 |

Correction method |

Automatic EPC control, stroke 50mm |

|

|

5 |

Feed roll materials method |

Roll materials with 3-inch inflatable shaft fixed; |

|

|

Unwinding with single inflatable shaft |

|

||

|

6 |

Maximum unwinding diameter |

Ф250mm |

|

|

7 |

Maximum bearing capacity of inflatable shaft |

50Kg |

|

|

8 |

Number of unwinding inflatable shaft |

1 pcs |

|

|

9 |

Main drive motor |

Induction variable frequency motor |

|

|

10 |

Over roll surface treatment |

Metal aluminum roller surface oxidation |

|

|

11 |

Scraper structure |

Double-sided comma scraper |

|

|

12 |

Coating roller(steel roller) |

Surface hard chromium plating |

|

|

13 |

Back roller(rubber roller) |

Surface package imported EPDM |

|

|

14 |

Mixing device |

Prevent Slurry subside |

|

|

15 |

Material connecting platform |

Easy for materials changing |

|

Oven

|

No. |

Item |

Technical parameters |

Note |

|

1 |

Oven structure |

Double layer heating, arranged vertically, with hot air circulation |

|

|

2 |

Oven length |

1.5m/section, total 3 sections, three temperature control sections |

|

|

3 |

Material |

SUS304 stainless steel |

|

|

4 |

Temperature control |

Divided into normal working temperature control, over-temperature monitoring alarm protection control, all sections are completely independent control |

|

|

5 |

Heating method |

Analog signal control power heating, hot air circulation structure, accuracy±1℃ |

|

|

6 |

Single oven heating power |

9KW |

|

|

7 |

Oven internal temperature |

DesignMax150℃,Single section oven internal temperature difference≤ 2.5℃ |

|

|

8 |

Blowing method |

Upper and down blowing, upper and down wind chamber shared heating body |

|

|

9 |

Wind nozzle structure |

slotted using a specialized precision mold |

|

|

10 |

Fan control |

Contactor control |

|

|

11 |

Heating control |

Temperature control analog signal solid-state relay automatically controls power heating, with high accuracy and long service life |

|

|

12 |

Fan material |

SUS304 stainless steel |

|

|

13 |

Solvent recovery system |

Optional |

|

Winding mechanism(same function with unwinding)

|

No. |

Item |

Technical parameters |

Note |

|

1 |

Running correction |

Installed at the exit of the oven |

|

|

2 |

Winding correction |

Installed at the winding device |

|

|

3 |

Tension |

Two sets of floating roller sensor motors with constant tension control |

|

|

4 |

Installation structure method |

Steel frame firmly installed |

|

|

5 |

Number of winding inflatable shaft |

1 pcs |

One-armed winding |

4. Control system:

|

No. |

Item |

Technical parameters |

Note |

|

1 |

Main control system |

HIM Touch screen, PLC, servo system |

|

|

2 |

Running mode |

Manual, automatic, emergency stop, front and back of the whole machine can operate |

|

|

3 |

Alarm |

When the device fails, the touch screen will display the corresponding correction screen |

|

Dimension:L 6500*W 1200*H 1800mm ; Weight about 2000kg , With Wheel base.

Hardware accuracy

|

No. |

Item |

Technical parameters |

Note |

|

1 |

Scraper |

Round beating≤±1.5um,Ra0.4,straightness≤±1.5um |

|

|

2 |

Coating roller(steel roller) |

Round beating≤±1.5um,Ra0.4straightness≤±1.5um |

|

|

3 |

Glue roller |

Round beating≤10um,straightness≤10um |

|

Installation environment requirements

1) Machine head ambient temperature25~30℃,others 10~40℃.

2) Machine head relative humidity: positive RH ≤35% (according to materials), negative RH ≤98%,others ≤98%.

Other requirements

1) Power supply:3PH ,AC380V,50HZ, Voltage fluctuation range:+10%~–10%;start total power 30KW.

2) Compressed air:After drying, filtering, and stabilizing, the exhaust pressure is around 0.5 MPa.

Product Display

More Other Models Coating Machine For Battery Electrode

Email : tob.amy@tobmachine.com

Skype : amywangbest86

Whatsapp/Phone number : +86 181 2071 5609

Previous:

Single Side Slot Die Battery Coating Machine For LabNext:

Battery Separator Coating MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.