Brand:

TOB NEW ENERGYitem no.:

TOB-SFX-08order(moq):

1 setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMEN8+1 Channels OCV Sorting Machine for Prismatic Cells

SPECIFICATIONS

Optional Protective cover

Overview:

Screening and pre-processing of cells before assembly, with OCV test and NG removal function.

Manually feed the cells into the feeding line of the OCV sorter. The sorting machine with functions of automatic feeding, automatic scanning of cells codes, automatic sorting and matching groups, automatic grouping of cells by the robotic arm, finally, the cells are collected manually.

Functions and Principles:

The 8+1 channels OCV sorting machine is used for prismatic cells code scanning, cells testing, and upload the data to the database, which can be connected to the customer's MES for real-time monitoring and retrieval.

L2100-W2000-H2200(The actual size is subject to design)

Top view analysis diagram of each workstation of the equipment

Equipment action process

Equipment Action Description:

When the employee places the battery on the battery cell, the device can be started by loading and pulling the strap. The front end of the cell feeding mechanism detects the battery, and the feeding cylinder acts to clamp the cell. After scanning the code and conducting voltage internal resistance tests on the cell, the assembly line sends it to the sorting station. After the detection is completed, it is recorded by the detector into the industrial control computer, and the motion sorting robot has PC instructions to match the gears.

1. The material retrieval testing and sorting machine can detect the voltage internal resistance of the product without distinguishing between cathode and anode.

2. If different voltage internal resistance products need to be detected and paired, the set gear needs to be changed on the PC.

3. It is recommended to replace the probe once a month.

Overall appearance of the equipment

1. Appearance: The load-bearing chassis adopts a square welded structure, the upper sealing frame adopts an aluminum alloy profile structure, and the organic glass is used for sealing.

2. Operation interface: Each device is equipped with an independent industrial control computer (computer) and touch screen for easy operation and maintenance.

3. The layout and installation direction of the equipment shall be designed according to the layout diagram attached to the technical agreement.

Equipment technical parameters

1. Product qualification rate: 99.5% (only referring to product scrapping caused by equipment reasons).

2. Equipment capacity/speed: ≥ 20PPM (slightly different depending on employee proficiency).

3. Equipment utilization rate: ≥ 95% (faults caused solely by equipment).

4. Equipment electrical: voltage 220V 60Hz; Voltage fluctuation is less than ± 10%; Equipment power: 2.5KW.

5. Air source requirements: ≥ 0.6Mpa (provided by the customer).

6. Voltage measurement resolution: 0.1mV.

7. Voltage range of the measuring instrument: 20V Accuracy: ± 0.01% rdg. ± 3dgt.

8. Resistance range of the measuring instrument: 3 Ω and 30m Ω Accuracy: ± 0.5% rdg. ± 5dgt.

9. Machine design should achieve excellent ergonomic performance.

10. Applicable battery range: 100-180mm (width) * 20-60mm (thickness) * 50 * 120 (height) mm.

Detailed Explanation of 8+1 Sorter Station

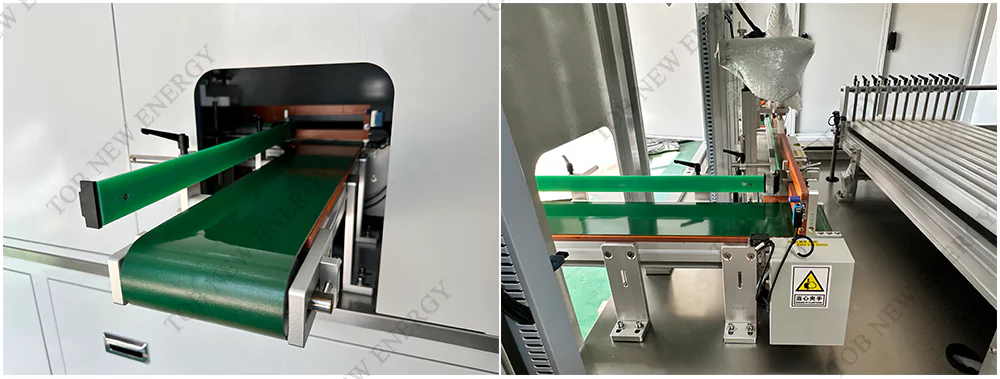

1. Feeding mechanism:1 set. The feeding assembly line is composed of a motor and a positioning mechanism for a mobile module. Employees place the battery on the material slot, and the battery is fed in sequence.

2. Battery detection and scanning mechanism:1 set, consisting of an internal resistance meter, scanning gun, positive and negative electrode detection clamping mechanism, battery positioning mechanism, and displacement discharge mechanism. Intermittent mobile feeding detection, with the completed battery waiting for the robotic arm to remove the grading.

3. The 8+1 sorting assembly line material trough: 9 sets. The tested batteries are divided into different levels by the mechanical arm according to the data set for each level. The batteries flow out and are waiting for employees to take them away.

4. Grading manipulator:1 set, consisting of 1 independent sorting manipulator, motor, module, clamping and positioning mechanism. When the battery reaches the corresponding gear, the manipulator places the battery in the matching gear.

PRODUCT DISPLAY

Conventional models:

Optional models (Required custom cost)

Email: tob.amy@tobmachine.com

Skype: amywangbest86

Whatsapp/Phone number:+86 181 2071 5609

Previous:

Prismatic Cell Sorter Battery Sorting MachineNext:

Manual OCV Multi-Functional Sorting Machine for Pouch CellIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.