Brand:

TOB NEW ENERGYitem no.:

TOB-DSP-Sorder(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMEN

SPECIFICATIONS

The battery electrode comma blade coating machine is a high-precision, high-efficiency coating equipment designed for new energy fields such as lithium batteries and supercapacitors. It uses a comma blade as the core coating tool, which can evenly and accurately coat the slurry on metal foil (such as copper foil, aluminum foil) to form the positive or negative electrode of the battery. This battery electrode coating machine is widely used in the electrode manufacturing fields of lithium-ion batteries, supercapacitors, fuel cells, etc., and is an indispensable key equipment in the battery production process.

Product Features

High-precision coating

Comma blade scraping technology is used to ensure uniform coating thickness.

A wide range of coating thickness can meet different needs from 5 microns to 250 microns.

Versatile applicability

Applicable to a variety of slurries (such as positive electrode slurry, negative electrode slurry) and substrates (such as copper foil, aluminum foil).

Coating width and thickness can be customized according to customer needs.

Stable and reliable

Adopt high-precision transmission system and tension control system to ensure smooth operation of the substrate.

Key components (such as comma blade, drying system) are made of high-quality materials and are durable.

| 1.Base materials | |||||

| Name | Corrosion aluminum foil | Copper foil | |||

| Width | 50~320mm | 50~320mm | |||

| Thickness | 15~50um | 6~20um | |||

| Areal density | 27~135g/m2 | 53~178g/m2 | |||

| 2.Coating methods | |||||

| 1)Comma roll + microgravure coating | |||||

| 2)Comma roll: Continuous & Intermittent, microgravure: Continuous, can be set on the touch screen | |||||

| 3.Drying | |||||

| 1) Oven length: 4000mm, 2000mm / section | |||||

| 2) Airflow radiation belts and rollers | |||||

| 3) Electric heating | |||||

| 4. Machine speed | Max7.5m/min | ||||

| 5. Coating speed | 1~7.5m/min(related to fluid state and the coating thickness ) | ||||

| 6. Coating process parameters | |||||

| 1) Continuous coating, the coating can be fixed length | |||||

| 2) Min interval length: 5mm | |||||

| 3) Max interval length: 250mm | |||||

| 4) Head and tail thickness control: | |||||

| By controlling the specific point in time to achieve and rubber tire wheel base ratio | |||||

| 7.Coating Precision | ±1.5% (related to the fluid state) | ||||

| 8.Tension range | 15 ~ 50N | ||||

| 9.Rollers width | 350mm | ||||

| 10.Roller diameter | General, 50mm, | ||||

| 11.Wind mouth Width | 350mm | ||||

| 12. NMP recovery system | Optional | ||||

| 13.Matching demand | |||||

| 1) Power distribution | AC220V, 50 / 60Hz, Max20KW, grounding resistance ≤10Ω | ||||

| 2) Machine size | Machine size:L x W x H = 3.5*1.2*1.5M | ||||

| 3) Compressed air | Maximum pressure not less than 0.5MPa | ||||

| 4) Exhaust emissions: | Reserve at least 400 * 400mm Or 400mm diameter exhaust outlet four | ||||

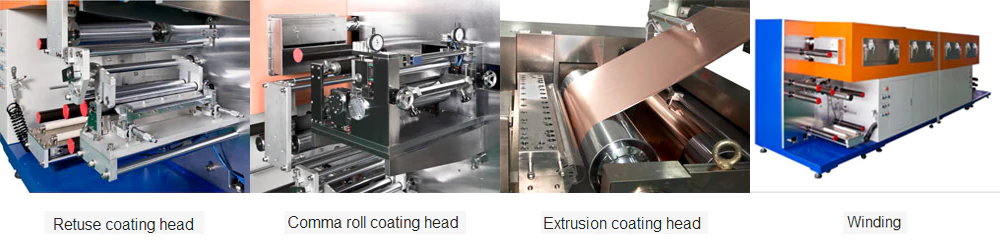

PRODUCT DISPLAY

Get More Battery Coating Machine According to Your Requirements

Email : tob.amy@tobmachine.com

Skype :amywangbest86

Whatsapp/Phone number :+86 181 2071 5609

Previous:

Conductive adhesive coating on the Cu mesh or Al mesh machineNext:

6M Drying Oven Battery Continuous and Intermittent Coating MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.