1100℃ High Temperature Vacuum Chamber Atmosphere

Furnace

SPECIFICATIONS

Overall overview of the Atmosphere Furnace:

Main uses: ceramics, metallurgy, electronics, glass, chemicals,

machinery, refractory materials, special materials, building materials,

universities, research institutes, industrial and mining enterprises to do

powder roasting, ceramic sintering, high temperature experiments, material

processing, quality universities, research institutes Industrial and mining

enterprises do high temperature atmosphere sintering, atmosphere reduction, CVD

experiments, vacuum annealing and so on.

This furnace uses silicon molybdenum rod as heating

element, double-layer shell structure and

30-stage program temperature control system, phase shift triggering,

thyristor control, furnace high quality high purity alumina fiber, vacuum

forming fiber poly light board material . A double furnace structure is used.

The furnace has the advantages of temperature field balance, low surface

temperature, fast temperature rise and fall, and energy saving.

Adopting international advanced technology, the

high-performance, high-energy-saving new type developed by ourselves adopts

energy-saving ceramic fiber material double-layer structure, which can reduce

the external temperature to normal temperature and make the inner cavity

temperature distribution uniform.

Technical Parameter

|

Item

|

TOB-Q1100-504040

|

|

Voltage AC

|

380V,50HZ

|

|

Heating power

|

18KW

|

|

Furnace

tube size (deep * width * height)

|

500x400x400mm

|

|

Furnace layout

|

|

|

Extreme working temperature

|

1100℃

|

|

Long-term working temperature

|

1000℃

|

|

Heating element

|

High

quality alloy resistance wire Installed around the furnace

|

|

Instrument control

|

Yudian

GP518P

|

|

Heating rate

|

1-20℃/min

adjustable

|

|

Recommended heating rate

|

3℃/min

Temperature rate

|

|

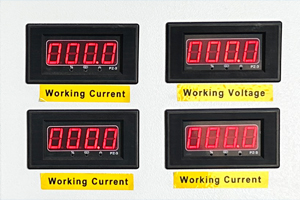

Temperature

control accuracy

|

±1℃

|

|

Temperature

display accuracy

|

±1℃

|

|

Digital display

|

Measuring

temperature, setting temperature double display

|

|

Atmosphere

|

Oxygen,

nitrogen, argon and other atmosphere

|

|

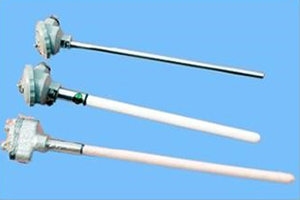

Temperature

measuring element and temperature range

|

K thermocouple, temperature range 0-1200 ° C, thermocouple close

proximity (contact) tube outer wall, can reduce the external temperature to

normal temperature and make the inner cavity

temperature distribution even.

|

|

Electric elements

|

CHNT

|

|

Sealing component

|

Silicone

ring + water cooling protection

|

|

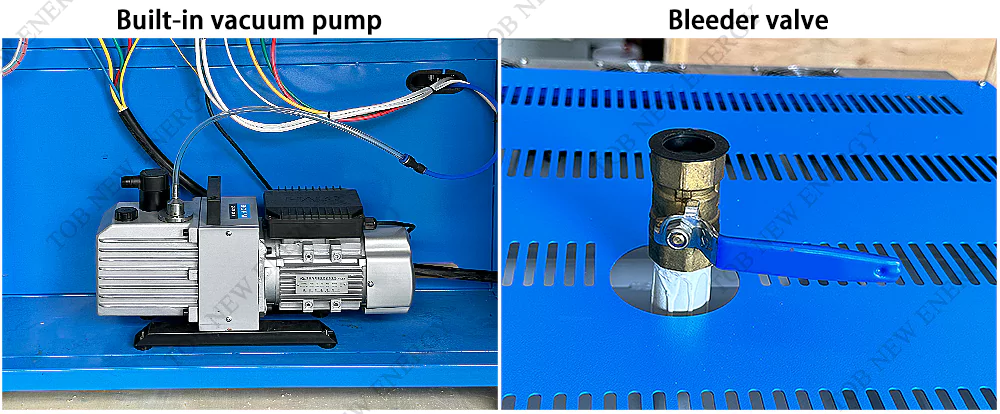

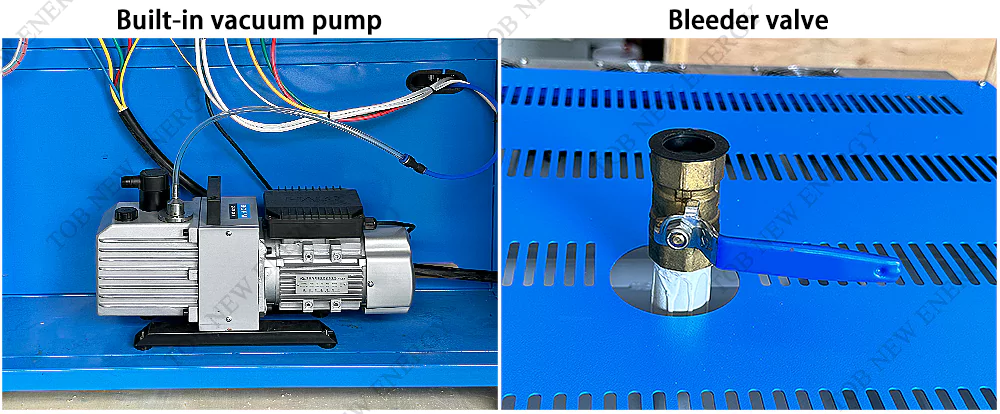

Vacuum system

|

<-0.1Mpa

|

|

Flow

meter (optional) Quoted price not include this

|

0-500ml/min

|

|

Control method

|

Control

mode:

Adopt automatic control system, it can run automatically after setting

the program from room temperature to set temperature. TheSystem SCR control,

the temperature control system is modular in design, the structure is simple,

and the maintenance is convenient.

It adopts yudian instrument, imported SCR control, programmable 30

sections, multi-section power limit function, multi-group PID parameter

self-setting function, can set constant temperature and heat preservation

curve freely, no interference switching function, the instrument has

temperature correction and compensation function.

|

|

Number

of programmed curve segments

|

30 segments are

adjustable to reduce unnecessary troubles caused by artificial settings.

|

|

Control features

|

Control system modular

structure, long life design of key components of the equipment, simple and

reliable process, good stability and high precision.

|

|

Air cooling system

|

The fan impeller is mounted directly on the bottom of the double

furnace shell and assembled with the control system. When the sintering

furnace is heated, air cooling can reduce the surface temperature of the

furnace shell and protect the heat of the electric appliance, and the

personnel operation is safer and the efficiency is improved.

|

|

Refractory matter

|

The

lining is made of high-quality high-purity alumina fiber, vacuum-formed

fiber-reinforced light-weight board material, light-weight hollow-balloon

alumina board, high temperature, low heat storage, resistance to rapid heat and

cold, no cracks, no slag, good insulation performance ( The energy saving

effect is more than 80% of the old electric furnace). The double-furnace

structure patent is a patented feature that not only heats up quickly, but

also has durability and long-term use without collapse.

|

|

Thermal insulation material

|

High-quality alumina

multi-fiber insulation material, insulation layer is 150mm.

|

|

Shell

|

The furnace shell is made of steel plate and profile welded, and the

outer casing is equipped with a removable protective plate. The protective

plate is electrostatically sprayed and painted. Fine workmanship and

beautiful appearance.

|

|

Furnace structure

|

Double-layer furnace shell structure, air-cooled circulation, reducing

the temperature of the shell. The surface temperature of the shell is < 60

degrees.

The surface of the inner furnace is coated with a high-temperature

alumina coating to increase the heating efficiency of the equipment and to

extend the life of the instrument.

The opening between the

furnace door and the furnace body is connected by hinges,

|

Product Display

Learn More Furnace From TOB NEW ENERGY

Email : tob.amy@tobmachine.com

Skype : amywangbest86

Whatsapp/Phone number : +86 181 2071 5609