Brand:

TOBitem no.:

TOB-1810Border(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMENAutomatic Battery Sorting Machine With Scan Code Function

SPECIFICATIONS

TOB-1810B automatic sorting machine is a universal equipment for automatic testing of internal resistance and voltage of cylindrical battery cells with 18650/21700/26650/26700/32650/32700. It comes with a high-precision internal resistance and voltage testing system. The equipment accurately sends the battery to the corresponding channel based on the internal resistance and voltage values set on the software. The system can achieve up to 11 levels of sorting, and can test about 3500-4500 battery cells per hour. The structural design is simple and the performance is stable.

Technological process

By setting parameters through software, the PLC automatically completes the following functions: manually placing the battery cells into the hopper → transporting the battery by the motor → automatically testing the voltage and internal resistance → automatically scanning the code → sending them into the corresponding channel slot according to the set parameters → recording and saving data → manually removing the battery cells

Sorting Machine

1. The equipment has a compact structure and a beautiful appearance.

2. The equipment operation is simple and does not require professional personnel.

3. The equipment is controlled by PLC, which is responsible for battery transportation, battery testing data collection, and voltage internal resistance level sorting.

4. The equipment adopts high-quality cold-rolled sheet metal paint structure.

5. Optional automatic connection interface for automatic padding machine.

6. The equipment is equipped with universal casters that can be easily moved.

7. Equipment configuration includes sound and light alarms, automatic shutdown upon completion of sorting, full material alarm, fault alarm, etc.

8. Operation interface: Chinese and English are optional.

Equipment Technical Parameters

| Equipment power | 1.6KW, 220V AC input, 50Hz/60Hz |

| 1.6KW, 110V AC input, 50Hz/60Hz (export specific, customized) | |

| Scope of application | 18650/21700/26650/32700 cylindrical battery cells (corresponding wave wheel need to be replaced) |

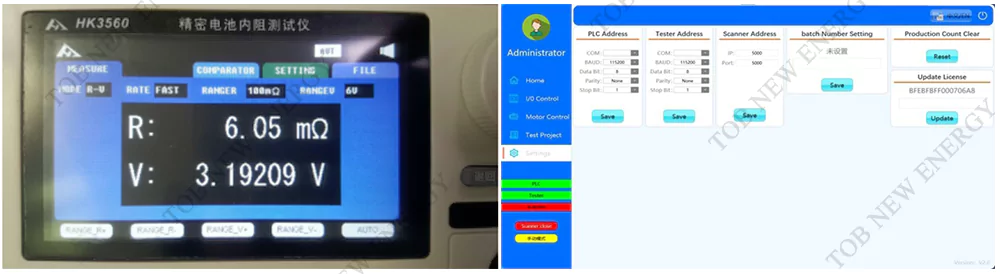

| Standard tester | HK3560 high-speed tester, voltage accuracy 0.00001V, internal resistance accuracy 0.01mΩ |

| Optional Tester | HK3561 tester, voltage accuracy 0.0001V, internal resistance accuracy 0.1mΩ |

| HIOKI BT3561A, Voltage accuracy 0.0001V, internal resistance accuracy 0.1mΩ | |

| HIOKI BT3562A, Voltage accuracy 0.00001V, internal resistance accuracy 0.01mΩ | |

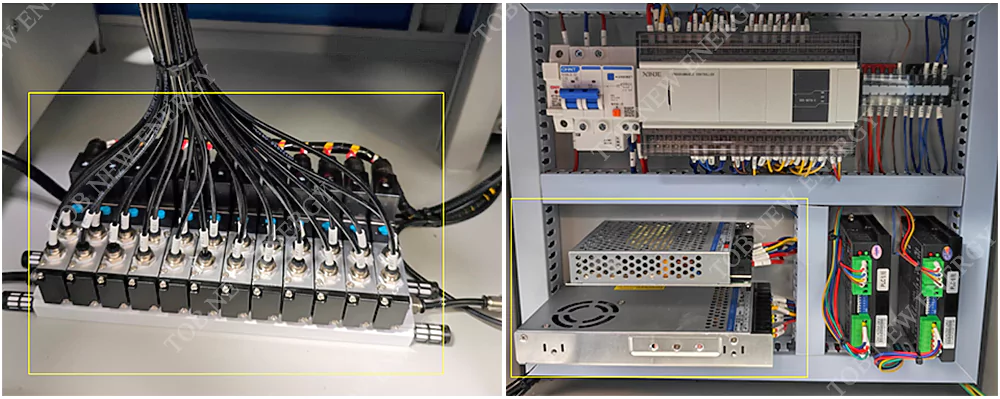

| Battery transfer mechanism | Adopts servo motor, equipped with planetary reducer, precise positioning and fast speed. |

| Gearing mechanism | Adopts servo motor, equipped with planetary reducer, synchronous belt transmission, precise positioning and fast speed. |

| Testing mechanism | Adopts 3250 DC motor, precise positioning and long service life. |

| Graded battery cell mechanism | Adopts 3250 DC motor, precise positioning and long service life. |

| Number of channels | 10 OK gears, 1 NG gear |

| Voltage setting | 0.00000V-6.00000V |

| Internal resistance setting | 000.00mΩ - 999.99mΩs |

| Production efficiency | Approximately 3500-4800 battery cells per hour |

| Test effect | Repeated testing, excellent effect |

| Control unit | Xinjie 6-Axis PLC Programmer |

| Motion components | The gear shifting adopts servo motors for precise positioning. |

| Equipment dimensions | L1038*W1598*H1550MM |

| Equipment weight | Approximately 260KG |

| Automatic collection of production quantity, display of current production efficiency, automatic scanning of code to record bound data, database format .mdb, data records saved on the local host of the sorting machine, and can be connected to the factory MES system database. | |

| Test data storage on USB drive. After shutdown, copy the data to the computer. The amount of data stored on the USB drive depends on the memory of the USB drive. When the storage space is insufficient, the earliest data will be automatically overwritten. The USB flash drive is provided by the customer, and this function is turned off on the device when the test data is not saved. | |

| Equipment debugging is simple, easy to learn and understand, with built-in fault alarms. | |

Equipment Configuration List

|

Name |

QTY |

Spec. |

|

PLC |

1PCS |

|

|

Display |

1PCS |

|

|

IPC |

1PCS |

|

|

Graded servo motor |

1PCS |

57HB80-0821 |

|

Discharge servo motor |

1PCS |

60HB100-0821S |

|

Servo motor driver |

2PCS |

DM2405M |

|

Graded synchronous belt |

1PCS |

25-889-25 |

|

Graded pushing cylinder |

10PCS |

TDA10-30 |

|

DC motor control motherboard |

1PCS |

3560-V0 |

|

Standard tester |

1PCS |

HK3560 |

|

Test needle |

20PCS |

PH-18M23L |

|

Sensor |

1SET |

|

|

Switch power supply |

1PCS |

LM150-20B24 |

|

Switch power supply |

1PCS |

LM350-10B48 |

|

Accessories |

1SET |

|

|

Control system |

1PCS |

|

|

Equipment frame |

1PCS |

Aluminum alloy frame, sheet metal with baking paint |

Operating Environment

Indoor temperature: -30℃~70℃.

Indoor humidity: below 75%.

Factory site: no pollution or strong electromagnetic interference.

Get More Information of Battery Sorting Machine

Email : tob.amy@tobmachine.com

Skype : amywangbest86

Whatsapp/Phone number : +86 181 2071 5609

Previous:

Battery Automatic Sorter MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.