Brand:

TOB NEW ENERGYitem no.:

TOB-S-DP300order(moq):

1setPayment:

L/C, T/Tproduct origin:

Chinashipping port:

XIAMENTOB NEW ENERFY Semi-automatic Battery Electrode Stacking Machine

SPECIFICATIONS

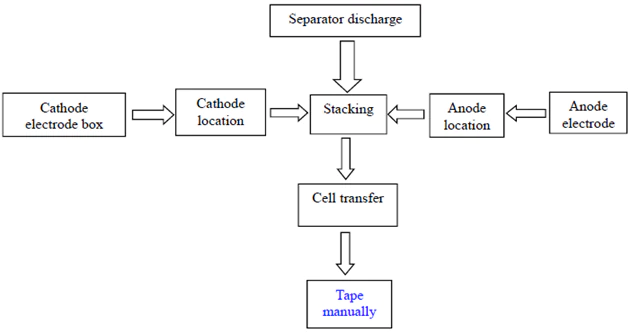

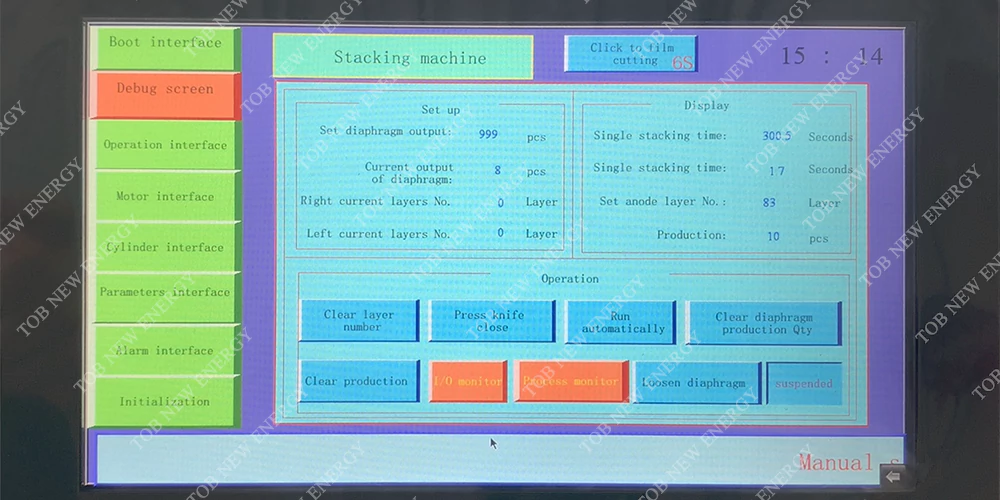

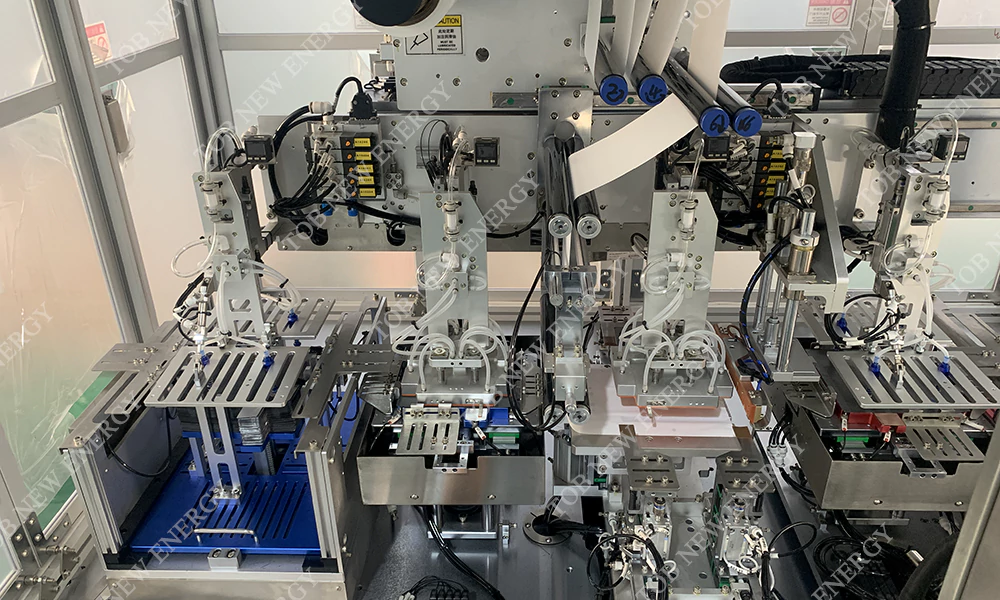

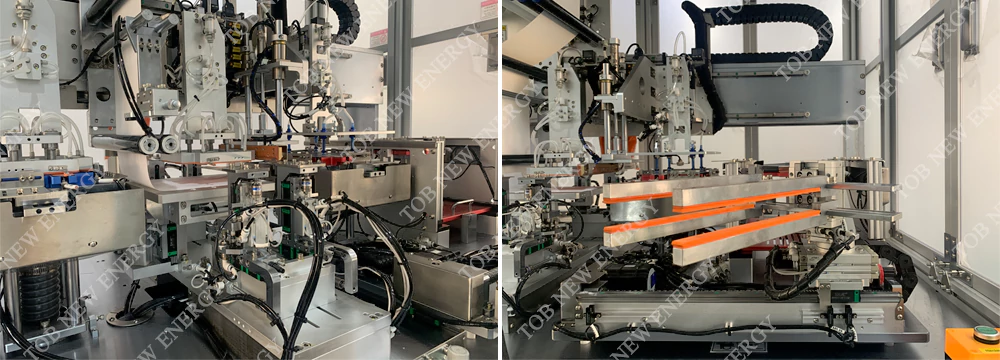

This battery stacking machine is used for lithium power battery stacking process, it dopts Z stacking. The separator discharge by motor, through tension, correct, to stacking plate; The Manipulator mechanism reciprocating movement left and right, through chuck institutions to take the electrode from materials box, after secondary locating platform to put the electrode on the stacking plate. At the same time, the separator is driven to move left and right; there are four sets of pressing knife mechanisms on the lamination table to press the electrodes crosswise; after the lamination is completed, the separator is cut off, take out the cell from transfer structure and then tape by manual, take the cell by manual; at the same time start the automatic stacking of the next cell.

Work process

Features

1. Presser buffer mechanism: before presser exit, micro lift away from the electrode to prevent pulling the electrode.

2. Separator auto unwinding, tension control, deviation correction, effectively ensure the precision of separator alignment.

3. Through the precise positioning of the electrode, the position accuracy of the electrode during stacking can be guaranteed effectively.

4. A variety of measures to effectively control the phenomenon of material leakage: material box blowing mechanism, sorting brush, external sucker manipulator shake.

5. The material box and the secondary positioning are equipped with effective dust collection mechanism.

Material Specifications

|

M/S |

Material |

Length (mm) |

Width (mm) |

Thickness (mm) |

Inner diameter (mm) |

Outside diameter (mm) |

|

Electrode |

sheet |

150-300 |

80~150 |

0.07~0.25 |

---- |

---- |

|

Tab |

---- |

8~20 |

8~80 |

---- |

---- |

---- |

|

Separator |

roll |

---- |

150-300 |

0.02~0.04 |

φ76.2 |

φ300 |

Note:

1. The length of the electrode indicates the size of the electrode in the direction of the tab, excluding the length of the tab.

2. The electrode has no obvious powder drop phenomenon and no obvious wave edge; the die-cutting error is less than 0.2mm.

3. There is no obvious warpage and deformation in the incoming electrode, and there is no obvious adhesion in the incoming electrode.

4. Separator serpentine bending error: 1mm/1000mm.

|

Item |

Parameter |

|

Stacking speed |

1.3~1.6s/pcs |

|

Auxiliary time |

15~20s |

|

Center deviation ±0.4mm |

|

|

End face alignment accuracy of separator |

±0.3mm |

|

Alignment accuracy of adjacent electrode |

±0.2mm |

|

Overall alignment accuracy of the electrode |

±0.3mm |

|

Stacking layers |

Can be set |

|

Outer cladding separator |

Machine empty stack reserved separator, manual tail winding, manual tape |

|

Product qualification rate |

99% (defects caused by this machine only) |

|

Utilization rate |

98% (faults caused by this machine only) |

|

Power |

2kw |

Working environment requirements

|

Item |

Spec |

|

Dimension |

W1600 x L1300 x H1850mm for reference |

|

Weight |

About 1000Kg;>450Kg/M2 |

|

Color |

Computer grey(If the buyer has color requirement, please provide color standard sample) |

|

Power |

AC220V Single phase;±10% |

|

Air compressor |

0.5~0.7Mpa(5~7kgf/cm²),Flow 100L/min |

|

Temperature |

5~35℃ |

|

Humidity |

5~55%HR |

|

Air/Dust |

Non-salty gases, toxic and corrosive gases;There should be no conductive dust |

|

Magnetic field and vibration |

There shall be no magnetic boundary affecting the device;There should be no shock and obvious vibration |

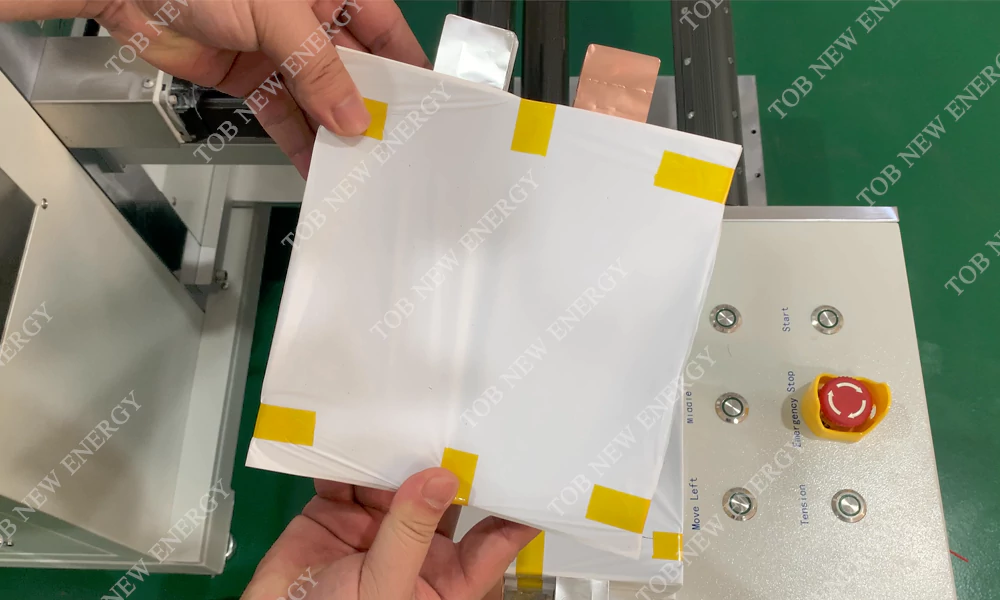

PRODUCT DISPLAY

More stacking machine for lithium ion pouch cell.

Email: tob.amy@tobmachine.com

Skype: amywangbest86

Whatsapp/Phone number: +86 181 2071 5609

Previous:

Automatic Battery Electrode Stacking Machine for Lithium Pouch CellNext:

Semi-auto Battery Electrode Stacking Machine for Lithium Pouch CellIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.