Brand:

TOB NEW ENERGYitem no.:

TOB-BZDP-2ZZGorder(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMENSemi-automatic Electrolyte Filling Machine for Prismatic Cell

SPECIFICATIONS

TOB-BZDP-2ZZG is used for precise quantitative electrolyte filling of prismatic cell. It has high injection efficiency, simple operation and good stability. It is an important equipment for advancedelectrolyte fillingprocess of prismatic cellproduction.

This is a 2-station electrolyte filling machine. It is small in size and can be operated in a glove box.

Working principle:

This machine consists of one set of jig, can be installed and disassembled 2PCS products at a time) adopts the absorption mode of vacuum fist and then liquid injection, manual loading and unloading, (optional manual weighing and scanning code), one person operation mode.

Structure consists of:

1. weighing and scanning code device (electronic scale, scanning gun).

2. battery fixture.

3. Liquid injection mechanism.

4. data storage system, and mechanical transmission and numerical control system. Fast, efficient and accurate injection.

Work flow:

Vacuuming/ charge Nitrogen gas/standing( vacuum strength, vacuum holding time, standing time, cycle times, all can be set)

Manual weighing and scanning code (before filling) → manual clamp battery → Fixture automatic positioning and clamping → automatic vacuum pumping and liquid injection → nitrogen filling/standing/vacuum breathing circulation filling → manual discharge clamping, code scanning and weighing (after filling) (according to the sequence of code scanning and weighing before filling) → end of work (cycle work).

|

Item |

Parameter |

|

Model |

TOB-BZDP-2ZZG |

|

Equipment overall dimensions |

L860xW650xH950 mm |

|

Weight |

About 0.6 tons |

|

Color |

Sheet metal gray white, rack blue (customer provided color palette) |

|

Compressed air |

0.4-0.6Mpa, Gas flow: 100L/min. |

|

Vacuum source |

vacuum degree -0.095Mpa, |

|

Design capacity of filling cup |

MAX600G,product electrolyte retention ±1.5% |

|

Filling port diameter of battery |

3-5mm |

|

Nitrogen |

0-0.2Mpa |

|

Power supply |

AC220V |

|

Power |

1.5KW |

|

Project |

Technical Instructions |

Description |

|

Efficiency max |

0.1PPM |

Total filling standing time within 20 minutes, the longer the time, the lower the efficiency |

|

Activation |

≧95% |

Statistical data for continuous production of 24 hrs |

|

Filling accuracy |

±3‰ |

Using empty case, each filling head do filling once, sampling once, sampling 20 times for each filling head, must meet the requirements of this specification; |

|

Qualified rate |

≧99% |

According to the tolerance of ±3‰; |

|

Suitable battery dimension |

The demander shall provide the size requirements and drawings of the cover plate |

Battery size for this device |

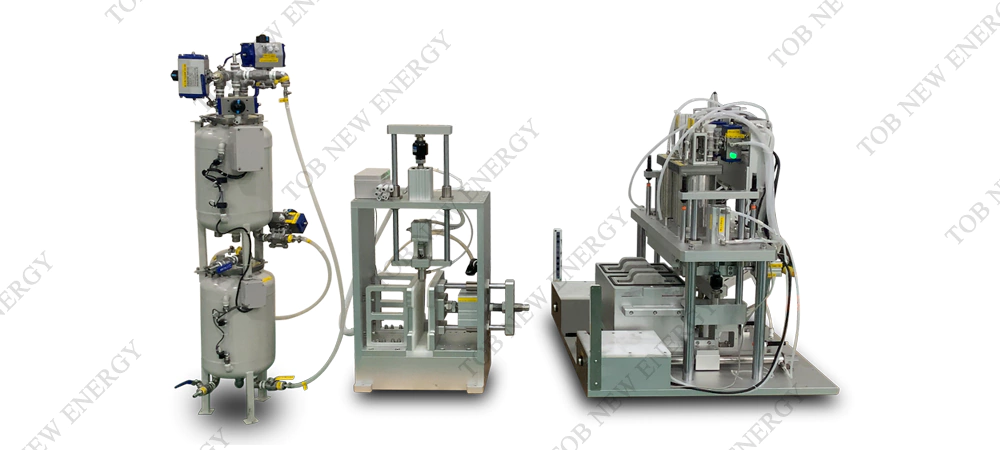

Product Display

Email : tob.amy@tobmachine.com

Skype : amywangbest86

Whatsapp/Phone number : +86 181 2071 5609

Previous:

Automatic Battery Electrolyte Filling Machine System For Prismatic Power Battery Pilot LineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.