Researchers at Stanford University have recently created a new

"smart" electrospinning separator with a thermal triggering

mechanism that contains a flame retardant that can be used to prevent lithium-ion

battery combustion.

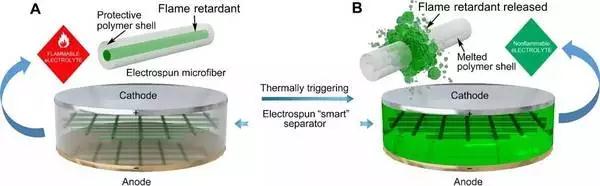

In

such a structure, the flame retardant is packaged in the inside of the polymer

protection shell to prevent the flame retardant from directly dissolving into

the electrolyte, thereby adversely affecting the battery performance.

When the heat inside the lithium battery is too high, the polymer

protective shell will be dissolved because of high temperature, the release of

flame retardants, which effectively inhibit the highly flammable electrolyte

combustion.

The

structure and function of this new electrospinning ultrafine fiber separator

are as follows:

The

description of the graph is as follows:

(A)This

separate separator consists of ultra-fine fibers, with a "core-shell"

structure, flame retardant in the core, the polymer is the shell. Flame

retardants are packaged in the interior of the polymer protection shell to

prevent direct dissolution in the electrolyte and cause side effects on

the electrochemical performance of the cell.

(B)When the

heat is too high after the trigger, the polymer protective shell dissolved, and

then packaged in the internal release of the flame retardant into the

electrolyte, effectively preventing the electrolyte ignition and combustion.

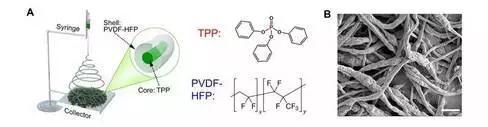

In

addition, the scientists also mentioned in the paper of the ultra-fine fiber separator material and the manufacture of microscopic diagram:

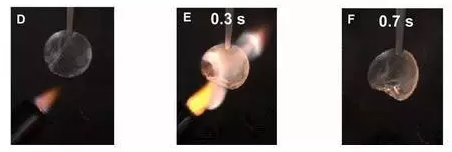

Flame retardants use a cheap, powerful, commonly used material "triphenyl phosphate." During normal operation of the cell, the flame retardant is well contained within the polymeric protective shell, which dissolves when the temperature of the separator is above a certain temperature. In the experiment, the flame retardant completely extinguished the electrolyte fire only 0.4 seconds, as shown below 0.3 seconds when the lithium battery on fire, 0.7 seconds when the fire was extinguished.