Brand:

TOB NEW ENERGYitem no.:

TOB-Agate Mortar-60order(moq):

1setPayment:

L/C,T/Tproduct origin:

Chinashipping port:

XIAMENHigh Quality Natural Agate Mortar and Pestle Supplirs

SPECIFICATIONS

In battery research and manufacturing, agate mortars have become important experimental tools due to their unique physical and chemical properties, especially playing a key role in material preparation and sample processing. The following are its main applications:

1. Preparation of electrode materials

Active material grinding: used to grind positive and negative electrode materials (such as lithium cobalt oxide, graphite, etc.) into fine powder to ensure uniform particles and improve battery performance.

Composite material mixing: used to evenly mix active materials, conductive agents and binders to ensure the consistency of electrode materials.

2. Research on solid electrolytes

Electrolyte powder preparation: used to grind solid electrolyte materials (such as sulfides and oxides) into ultrafine powders to promote ion conduction.

Uniform mixing: used to mix electrolyte materials of different components to ensure their stable chemical and physical properties.

3. Preparation of nanomaterials

Nano-particle grinding: used to prepare nano-scale electrode materials to improve the energy density and charge and discharge rate of batteries.

Surface modification: used to treat the surface of nano-materials to improve their electrochemical properties.

4. Sample pretreatment

Sample grinding: used to grind battery materials into powder suitable for analysis, which is convenient for subsequent characterization.

Uniform sampling: ensure uniform samples and improve the accuracy of experimental data.

5. Quality Control

Material Testing: Used to grind and mix materials to ensure they meet quality standards.

Batch Consistency: Ensures that the performance of materials in different batches is consistent, improving the stability and reliability of batteries.

Precautions for use

Cleaning and drying: Clean and dry immediately after use to avoid contamination.

Force control: Grind with moderate force to avoid damaging the agate mortar.

Uniform grinding: Ensure that the material is ground evenly to avoid excessive local wear.

Safety protection: Wear protective equipment during operation to ensure safety.

1. No cracks, no impurities, strong anti abrasion resistance.

2. High-quality products gloss, strong corrosion resistance, can be used in acid polishing materials.

3. For mixed grinding solid material or solid powder.

4. Should be particularly careful in the use of the process, not grinding hardness too much material, not contact with hydrofluoric acid.

5. Grinding operation, mortar should be put in is not easy to slide objects.

6. pestle should keep vertical.Mortar can not heating, do not put into the electric.

Packing: 1pcs agate mortar and 1pcs pestle,

Diameter Size

|

50mm |

60mm |

70mm |

80mm |

90mm |

|

100mm |

110mm |

120mm |

130mm |

140mm |

|

150mm |

160mm |

170mm |

180mm |

190mm |

|

200mm |

|

|

|

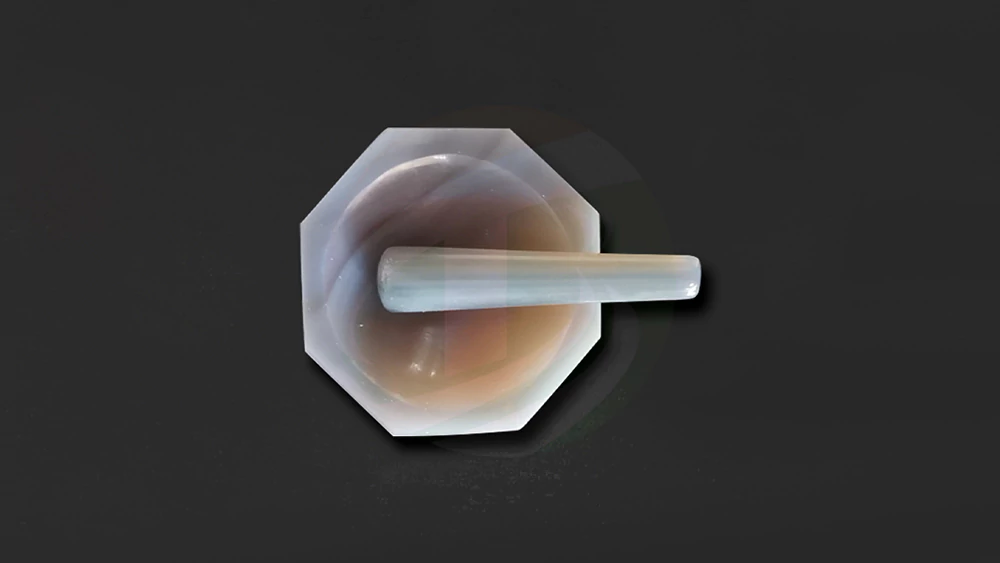

PRODUCT DISPLAY

Get More Battery Research and Manufacturing Machine

Email : tob.amy@tobmachine.com

Skype :amywangbest86

Whatsapp/Phone number :+86 181 2071 5609

Previous:

Best price Agate Mortar and Pestle suppliersNext:

Natural Agate Mortar and Pestle suppliersIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.