In the manufacturing process of lithium-ion batteries, formation is a critical procedure. This article discusses the impact of formation conditions (e.g., formation current, formation voltage, formation temperature, and external pressure) on battery performance, including internal resistance, capacity, and cycle life. TOB NEW ENERGY provides battery formation machine of various specifications to meet the production needs of battery laboratory research and battery production lines.

Formation refers to the initial charging process after electrolyte injection and rest, during which the solid electrolyte interphase (SEI) layer is formed. Variations in formation protocols result in slightly different SEI layers. The morphology of the SEI layer directly affects cell performance, such as rate capability, high-voltage stability, and particularly cycle life.

Below is a detailed analysis of how formation conditions influence cell performance:

1. Formation Current

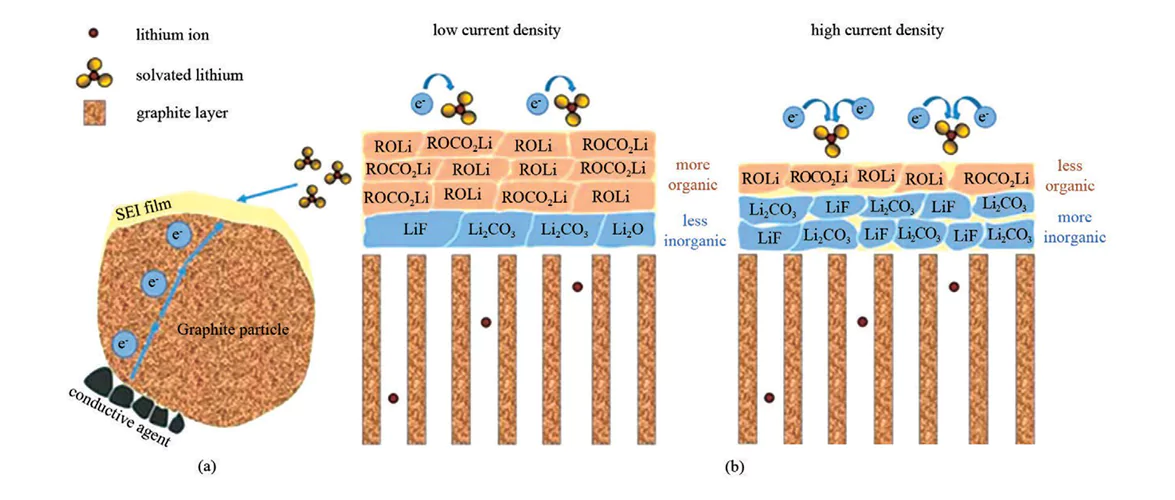

Studies show that lower current densities facilitate the formation of a robust SEI layer. The SEI formation involves two stages: nucleation and growth. High current densities accelerate nucleation, leading to a porous SEI structure with poor adhesion to the anode surface. Conversely, low current densities slow nucleation, producing a denser SEI layer. However, a porous SEI can better infiltrate the electrolyte, resulting in higher ionic conductivity compared to SEI formed under low current densities.

Traditional low-current pre-charging methods help form a stable and dense SEI, but prolonged low-current charging increases SEI impedance, negatively impacting rate capability and cycle life. Additionally, low-current formation prolongs production time, reducing manufacturing efficiency. To address this, a stepwise current formation protocol during the constant-current (CC) phase has been proposed. This approach reduces polarization, improves charge capacity, shortens formation time, and enhances efficiency.

Figure 1(a) SEI formation on graphite surfaces during formation and (b) the effect of formation current density on SEI structure.

2. Formation Voltage

Different formation voltages significantly affect electrode surface conditions, internal resistance, and cycle performance. For example, a study comparing cutoff voltages of 3.5 V and 4.2 V found that a 4.2 V cutoff yielded higher charge capacity but 4.1% lower charge-discharge efficiency than 3.5 V. Batteries formed at 4.2 V exhibited higher electrode resistance and faster cycle degradation.

3. State of Charge (SOC)

SOC is a critical parameter in formation optimization. Coupled with charge/discharge voltage, varying SOC levels during aging induce different degrees of reactivity, altering SEI properties and ultimately battery performance. Experimental results indicate that 25% SOC leads to higher impedance and lower capacity retention before and after aging. The optimal protocol involves charging to 100% SOC, discharging to 25% SOC (i.e., maintaining 75% SOC), by aging at room temperature. This method achieves the highest initial discharge capacity and capacity retention.

4. Formation Temperature

For polymer lithium-ion batteries, high-temperature formation promotes more complete SEI formation and enhances separator wettability, reducing gas generation. However, low-temperature formation favors slower lithium salt reduction, enabling ordered and dense SEI deposition, which extends cycle life. While high-temperature SEI layers exhibit higher ionic conductivity, their instability due to accelerated dissolution and solvent co-intercalation worsens cycle performance. Most manufacturers adopt high-temperature aging (30–60°C) to improve cycle and storage performance.

5. External Pressure

Gas generation during formation increases the distance between electrodes, lengthening Li-ion transport paths and raising impedance, thereby reducing capacity. Applying moderate pressure eliminates gas, ensures tight electrode contact, minimizes deformation, and improves formation capacity, rate capability, and cycle life. Post-mortem analysis reveals that insufficient pressure causes lithium plating on the anode, while optimal pressure prevents such defects.

Summary:

The formation process plays a decisive role in lithium-ion battery performance. Optimizing formation current, voltage, temperature, and external pressure is crucial for enhancing battery properties. However, individual parameter adjustments yield limited improvements. A holistic optimization strategy is essential to maximize battery performance.