The inconsistency of energy storage batteries mainly refers to the inconsistency of parameters such as battery capacity, internal resistance, and temperature. Our daily experience is that when two dry batteries are connected in positive and negative directions, the flashlight will light up, and we don’t consider consistency. However, once batteries are used on a large scale in energy storage systems, the situation is not so simple. When inconsistent batteries are used in series and parallel, the following problems will occur:

1. Loss of available capacity

In the energy storage system, battery cells (i.e. battery cells) are connected in series to form a battery pack, and battery packs are connected in series to form a battery cluster. Multiple battery clusters are directly connected in parallel to the same DC bus. The reasons for the loss of available capacity due to cell inconsistency include series inconsistency and parallel inconsistency.

(1) Loss of battery pack series inconsistency:

Due to inconsistencies such as differences in the battery cells themselves and temperature differences between battery packs, the SOC (remaining power) of each battery pack will be different. As long as one battery pack is full/empty, all battery packs in the cluster will stop charging and discharging.

Figure 1. Battery inconsistency causes series capacity mismatch

(2) Inconsistency loss of battery cluster parallel connection:

After the battery packs are directly connected in parallel to form battery clusters, the voltages of each battery cluster are forced to be balanced. When the battery cluster with smaller internal resistance is fully charged or discharged, the other battery clusters must stop charging and discharging, resulting in the battery clusters not being fully charged or fully discharged.

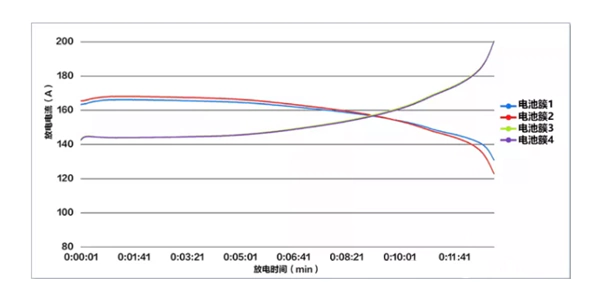

Figure 2 Current difference during discharge of multiple battery clusters in parallel

In addition, due to the small internal resistance of the battery, even if the voltage difference between each cluster caused by inconsistency is only a few volts, the uneven current between clusters will be very large. As shown in the measured data of a power station in the table below, the charging current difference reaches 75A (the deviation is 42% compared with the theoretical average value). The deviation current will cause overcharge and over-discharge in some battery clusters. It greatly affects the charging and discharging efficiency, battery life, and even causes serious safety accidents.

|

|

Charge/discharge |

Voltage |

Current |

SOC |

|

First cluster |

Charge |

793.2V |

-197.8A |

66 |

|

Second cluster |

Charge |

795.3V |

-126.6A |

77 |

|

Third cluster |

Charge |

792.8V |

-201.6A |

66 |

Table 1 Measured data of a power station

2. Shortened life of energy storage system

Temperature is the most critical factor affecting the life of energy storage. When the internal temperature of the energy storage system rises by 15°C, the life of the energy storage will be shortened by more than half. Lithium-ion batteries generate a lot of heat during the charging and discharging process. Due to the inconsistent internal resistance of the single cells, the temperature distribution inside the energy storage system will be uneven, the battery aging and attenuation rate will increase, and ultimately the life of the energy storage system will be shortened.

It can be seen that the temperature inconsistency of the battery in the energy storage system is an important factor affecting the performance of the energy storage system. It will reduce the available capacity of the energy storage system, shorten the cycle life of the energy storage system, and even cause safety hazards.

How to deal with the inconsistency of energy storage batteries?

The inconsistency of battery cells is formed during the production process and deepened during use. The weaker the battery cells in the same battery pack, the weaker they are, and the weaker they are. However, although there are no completely consistent battery cells, it is possible to integrate digital technology, power electronics technology and energy storage technology, and use the controllability of power electronics technology to minimize the impact of lithium battery inconsistency. In response to the problems caused by the inconsistency analyzed in the previous article, some manufacturers on the market have launched string energy storage systems, which have the characteristics of refined energy management and distributed temperature control, and can be used to treat the symptoms:

(1) Refined management to increase available capacity

Compared to the traditional PCS that manages more than 1,000 to 2,000 cells, the string energy storage system improves the cell management accuracy to more than a dozen, which is about 100 times higher. In view of the series mismatch between battery packs, the optimizer is designed to achieve separate charge and discharge management for each battery pack. When a battery pack reaches the set threshold, the battery pack is bypassed, and other battery packs can continue to charge and discharge without affecting each other, maximizing the use of battery capacity.

At the same time, each battery cluster is equipped with an intelligent cluster controller to avoid the impact of battery inconsistency caused by direct parallel connection, so that the charge and discharge current of each cluster can be accurately controlled with an error of less than 1%. This avoids the mismatch between clusters and truly realizes independent charge and discharge management between battery clusters, eliminates the generation of circulation, and further improves the capacity and safety of the system.

(2) Distributed temperature control to extend the life of the energy storage system

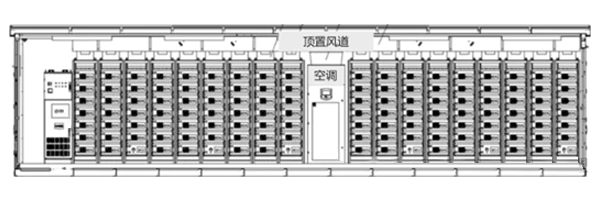

Traditional energy storage containers are equipped with 1-2 centralized air conditioners, and use longitudinal air ducts for heat dissipation. The length of the air duct is about 6 meters to 12 meters. Due to the long heat dissipation channel, the temperature consistency of each battery pack and battery cluster cannot be guaranteed.

Figure 3 Traditional centralized heat dissipation structure

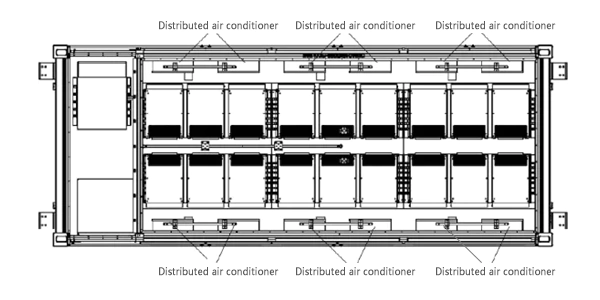

String energy storage uses cluster-level distributed heat dissipation, using distributed air conditioning instead of centralized air conditioning. Each battery cluster can dissipate heat independently and evenly, and the air duct length is less than 1 meter, which greatly improves the heat dissipation efficiency and avoids the temperature difference caused by the physical location. At the same time, the battery pack cleverly uses the tree-shaped bionic patented heat dissipation duct to adjust the length and distance of each battery cell duct, so that the cooling amount passed by each battery cell is as consistent as possible, reducing the temperature inconsistency of each surface of each battery cell.

Figure 4 Distributed heat dissipation structure diagram

Battery inconsistency is the root cause of many problems in current energy storage systems. However, due to the chemical characteristics of batteries and the influence of the application environment, battery inconsistency is difficult to eradicate. The string energy storage system greatly weakens the system's requirements for battery consistency through the controllability of power electronics and digital technology, which can greatly increase the available capacity of the energy storage system and improve system safety.