Lithium iron phosphate (LiFePO4) cathode electrode material oil-based slurry usually uses N-methylpyrrolidone (NMP), dimethyl sulfoxide and dimethylformamide as solvents, which have problems such as difficult solvent recovery, large amount of use and environmental pollution. LiFePO4 positive electrode material water-based slurry uses deionized water as solvent, which is environmentally friendly and low-cost, but the water-based binder positive electrode sheet has problems such as poor flexibility, weak adhesion of active materials and poor electrochemical performance. In this paper, positive electrode sheets with different NMP addition amounts were prepared to study the effect of NMP on the performance of positive electrode sheets prepared with water-based binder LA132.

Experiment

The aqueous binder LA132, superconducting carbon black, deionized water and LiFePO4 were prepared into slurry at a mass ratio of 2.5:2.5:50:40. Four portions of slurry were added with 0, 1%, 2% and 3% NMP, numbered A, B, C and D. Calendering the positive electrode. Drying the positive electrode at 100℃in a vacuum for 24h to remove water and NMP, and the positive electrode with an active material content of 95% was prepared. Cut it into 20mm diameter discs. Assemble CR2016 coin cell with lithium metal sheet negative electrode, 1 mol/LLiPF6/(EC+DEC+DMC) (volume ratio 1:1:1) electrolyte, microporous polypropylene separator, in a dry argon gas filled glove box.

First, bend the A, B, C, and D electrode sheets 180 degrees, and then test the adhesion of the electrode sheets on a tensile testing machine. Then, perform a toughness test on the electrode sheets on a toughness tester (the diameters of the shaft rods are 1, 2, 3, 4, 6, 8, and 10 mm, respectively), and observe whether there are cracks on the surface of the electrode sheets after winding. The battery charge and discharge test current density is 0.1C, and the test voltage is 2.5~3.5V.

Results and Discussion

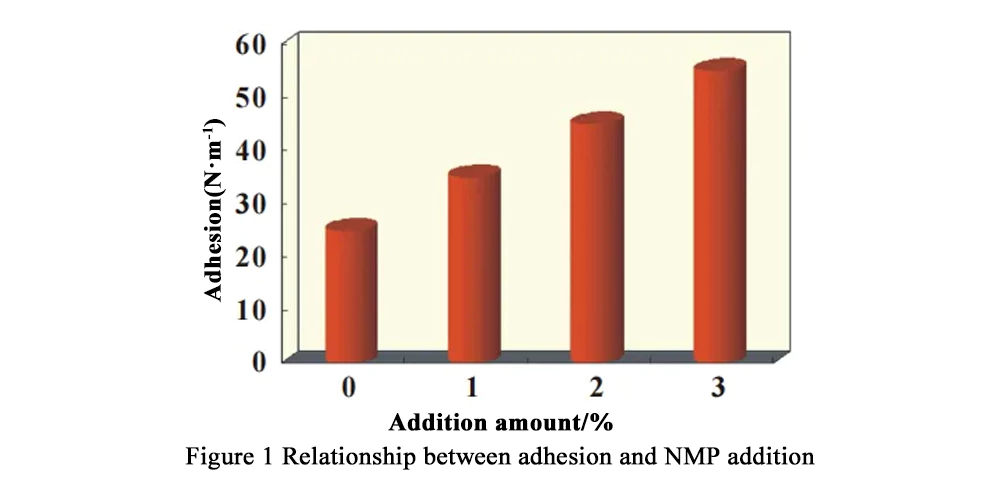

Figure 1 is a test diagram of the adhesion of the LiFePO4 electrode at 180°bending. It can be seen from Figure 1 that the adhesion of the electrode is significantly improved due to the addition of NMP, and the improvement of the adhesion of the electrode is proportional to the amount of NMP added. Adhesion is a type of van der Waals force, which depends on the interaction between molecules.

During the production process of LiFePO4 electrode sheets, the electrode sheets will inevitably come into contact with oxygen in the air. During the heating process, the heated electrode sheets react with oxygen to form acidic groups. The acidic groups lack electrons and will form weak intermolecular hydrogen bonds with (-CN) in the aqueous binder. It will change the thixotropy of the slurry, reduce fluidity, and cause uneven slurry coating. After adding NMP, it will neutralize the acidic groups on the electrode sheets. It can reduce the loss of electrons on the surface of the electrode sheets, prevent the slurry from thixotropy, and increase the adhesion between the binder and the current collector. The positive electrode slurry is evenly dispersed and the fluidity is improved, thereby improving the utilization rate of the slurry and the electrode sheets. Therefore, the addition of electron-rich solvent NMP can improve the performance of the battery.

Table 1 shows the results of the flexibility test of four types of electrode sheets. Observing Figure 1, it can be found that surface cracks appeared when the 6mm diameter winding needle tested the positive electrode A, and when the 1mm diameter winding needle was tested, the electrodes B~D did not have surface cracks. It can be seen that the poorest flexibility is the pure water-based positive electrode sheet, which is prone to cracks, breakage and tearing during preparation. Adding NMP can improve the flexibility of the electrode sheet and increase the utilization rate of the electrode sheet. The latex particles in the LA132 binder are strong polar polymers with strong intermolecular forces and poor twisting ability, and the electrode sheet is easy to break. With the addition of NMP, the diameter of the latex particles in the LA132 binder increases, the twisting ability increases, the molecular chain rotation ability decreases, and the flexibility of the electrode sheet is enhanced.

|

Table 1 Relationship between electrode flexibility and NMP addition amount |

|||||||

|

No. |

D10 |

D8 |

D6 |

D4 |

D3 |

D2 |

D1 |

|

A |

No |

Flexible |

Flexible |

Flexible |

Flexible |

Flexible |

Flexible |

|

B |

No |

No |

No |

No |

No |

No |

No |

|

C |

No |

No |

No |

No |

No |

No |

No |

|

D |

No |

No |

No |

No |

No |

No |

No |

Table 2 shows the electrochemical performance test results of the electrode sheet. The valuesof the first discharge specific capacity, charge and discharge efficiency, discharge median voltage and constant current ratio are basically the same. This shows that the addition of NMP has no effect on the discharge capacity and charge and discharge characteristics of the positive electrode active material of the positive electrode sheet.

|

Table 2 Electrochemical properties of the electrode |

||||

|

No. |

First discharge specific capacity /(mAh·g-1) |

Charge and discharge efficiency /% |

Discharge median voltage /V |

Constant current ratio /% |

|

A |

157.0 |

97.90 |

3.384 |

99.3 |

|

B |

157.1 |

98.10 |

3.386 |

99.4 |

|

C |

156.9 |

98.00 |

3.385 |

99.4 |

|

D |

157.0 |

97.90 |

3.385 |

99.3 |

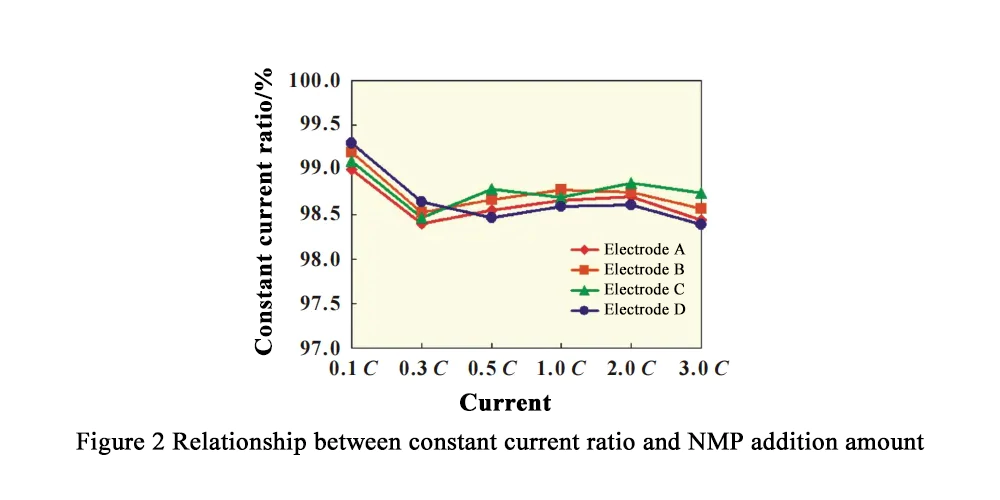

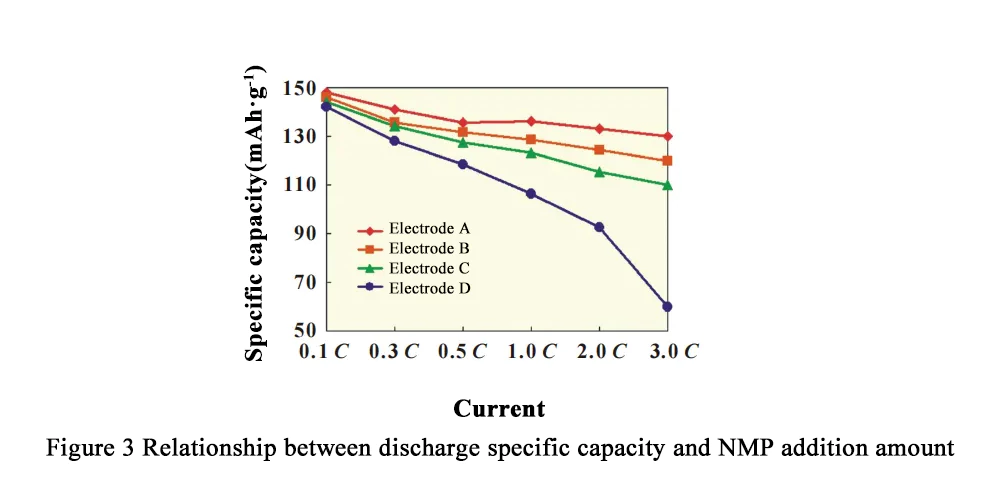

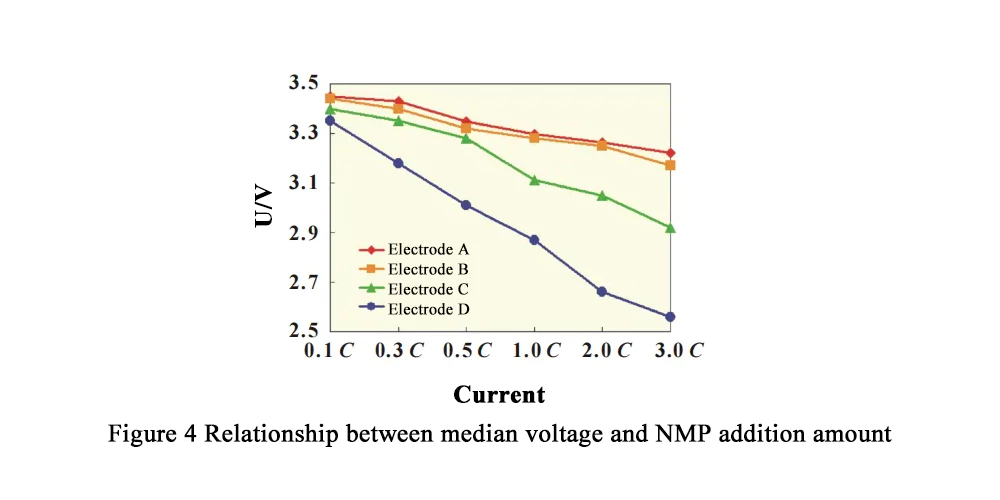

Figures 2 to 4 show the relationship between the constant current ratio, rate discharge specific capacity, discharge median voltage and NMP addition amount of the four electrode sheets.

From Figure 2, it can be found that under the same test conditions, the charging constant current ratios of the four batteries are all above 98.2%. From Figures 3 and 4, it can be found that the discharge specific capacity and median voltage of the same electrode sheet continue to decay with the increase of the discharge rate.

The discharge capacity and median voltage of electrodes A and B are basically the same at different discharge rates. As the discharge rate increases, the median voltage and discharge capacity of electrodes C and D gradually increase. It can be seen that when NMP is added at a concentration of no more than 1%, the rate discharge performance of the battery will not be affected. When NMP is added at a concentration of more than 1%, NMP will affect the discharge capacity and median voltage of the positive electrode.

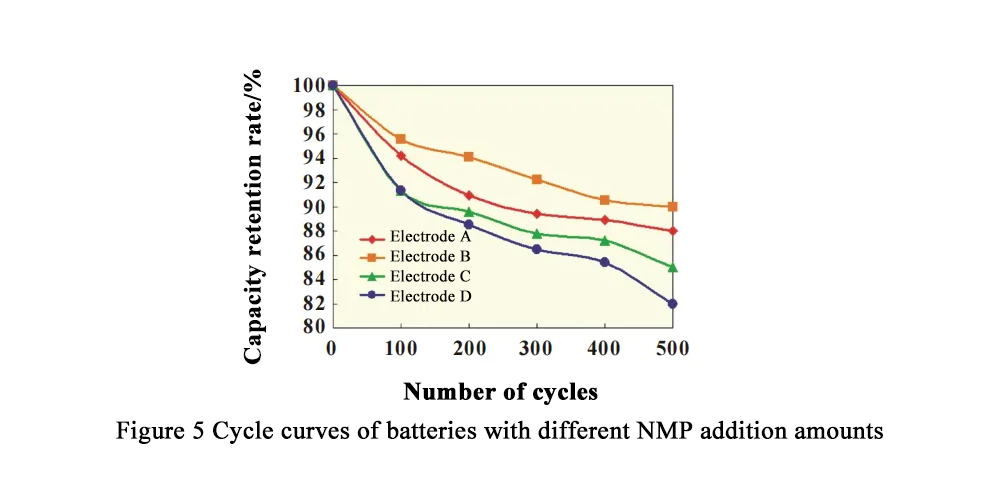

Figure 5 shows the cycle performance curves of the four types of batteries. By observing Figure 5, it can be found that at the beginning of the charge and discharge cycle, the capacity decay trends of electrode sheets A and electrode sheets B are similar, and the capacity decay trends of electrode sheets C and electrode sheets D are similar, while the decay rates of electrode sheets C and electrode sheets D are larger. As the cycle continues, the decay of electrode sheets A, C and D accelerates, and the decay rate of electrode sheet B remains basically unchanged. The final battery capacity retention rate is electrode sheet D<C<A<B. This shows that when the amount of NMP added is less than 1%, it is beneficial to improve the cycle characteristics of the battery, and when the amount of NMP added is greater than 1%, the cycle characteristics of the battery will be affected.

Conclusion

The adhesion of the positive electrode sheet can be improved by adding NMP, and the adhesion gradually increases with the increase of the amount of NMP added. After adding NMP, the acidic groups on the electrode will be neutralized, which can reduce the loss of electrons on the electrode surface, prevent the slurry from thixotropy, increase the adhesion of the binder and the current collector, make the positive electrode slurry dispersed evenly, and improve the fluidity, thereby improving the utilization of the slurry and the electrode. When the amount of NMP added is less than 1%, it will not affect the rate discharge performance of the battery and can improve the cycle characteristics of the battery. However, when the amount of NMP added is greater than 1%, NMP will affect the discharge capacity and median voltage of the positive electrode and reduce the cycle characteristics of the battery.