|

Prismatic cell |

Pouch cell |

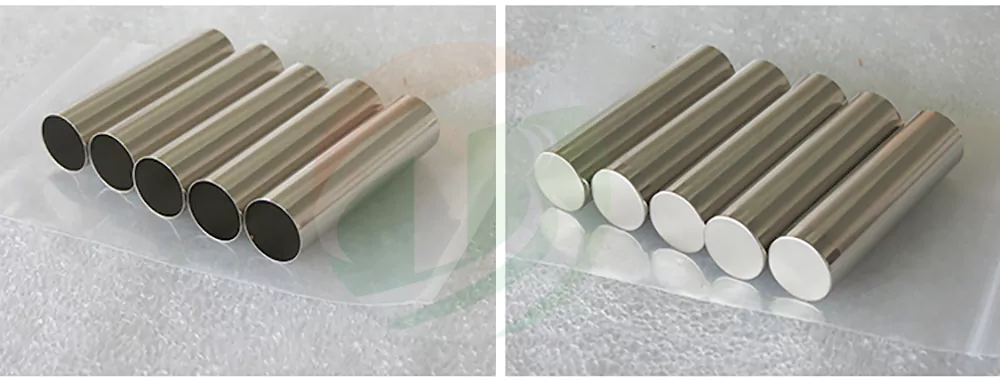

Cylindrical cell |

|

The aluminium housing is sturdy Safe and good cycle life |

The shell of the aluminum-plastic film material is prone to thermal failure, but it is not easy to explode |

The production process technology is mature The battery cells are packaged in a flexible group |

|

The single cell has a large capacity The number of modules is small Low monitoring and management risk |

It is easy to cause flatulence, and the battery cell is bulging and deformed After a long period of use, the battery life falls off a cliff |

The number of cells in the whole package is large Monitoring and management is difficult |

|

The packaging and manufacturing process is simple High reliability |

The pouch shell is weak Protection is required at the module level |

|

|

The consistency of the battery cell is average |

The cell is consistent |

The cell is consistent |

|

The energy density is average |

High energy density |

The monomer has a high energy density |

1.Cylindrical batteries:With a long development history, they are the most technologically mature.

Advantages: Mature technology leads to lower

costs, stability and durability, high energy density per cell, and good

consistency between cells.

Disadvantages: Limited room for improvement in

energy density, high requirements for BMS when combined in large quantities.

Common 18650 batteries are divided into

lithium-ion batteries and lithium iron phosphate batteries. Lithium-ion

batteries have a nominal voltage of 3.7V and a charging cut-off voltage of

4.2V. Lithium iron phosphate batteries have a nominal voltage of 3.2V and a

charging cut-off voltage of 3.6V. Their capacity usually ranges from 1200mAh to

3350mAh, with a common capacity of 2200mAh to 2600mAh. These batteries are

characterized by high capacity, high output voltage, good charge-discharge

cycle performance, stable output voltage, ability to discharge large currents,

stable electrochemical performance, safe usage, a wide range of operating

temperatures, and environmental friendliness.

The earliest cylindrical lithium battery, the 18650 lithium battery, was invented by Japan's SONY company in 1992. Due to the long history of the 18650 cylindrical lithium battery, its market popularity is very high. The structure of a typical cylindrical battery includes: positive electrode cap, safety valve, PTC element, current cutoff mechanism, gasket, positive electrode, negative electrode, separator, and shell. Cylindrical lithium batteries adopt a relatively mature winding process, with high automation, stable product quality, and relatively low cost.

It also has many models, such as the commonly seen 14650, 17490, 18650, 21700, 26650, etc. Taking 18650 as an example, "18" refers to the diameter of the battery cell being 18mm, "65" represents the height of 65mm, and "0" stands for its cylindrical shape. Other models follow the same pattern. It is widely used in solar lights, lawn lights, backup energy sources, electric tools, and toy models.

2.Prismatic battery:

Advantages: high strength, low internal resistance, long life, and high space utilization

Disadvantages: difficult to unify production

process and high heat dissipation difficulty

Prismatic batteries are currently the most

widely used battery PACK form in the international field. Currently, mainstream

domestic new energy automakers such as NIO and Geely use prismatic batteries.

One of the main reasons for the wide application of this battery is that there

are many suppliers and the technical difficulty is relatively low. Most

domestic battery suppliers choose to develop prismatic batteries. For example,

the well-known CATL mainly provides prismatic batteries.

Prismatic lithium-ion batteries usually refer to aluminum shell or steel shell prismatic batteries. Domestic power battery manufacturers mostly adopt aluminum shell prismatic batteries with higher battery energy density as the main product, because the structure of prismatic batteries is relatively simple. Unlike cylindrical batteries that use high-strength stainless steel as the shell and accessories such as explosion-proof safety valves, the overall weight of accessories of prismatic batteries is lighter compared to cylindrical batteries. Theoretically, the energy density of prismatic batteries is higher than that of cylindrical batteries. They have high structural strength, good ability to withstand mechanical loads, small battery internal resistance, long life, small decrease in energy density after assembly, and high space utilization rate.

3.Pouch battery:

Advantages: Extremely high energy density, light

weight

Disadvantages: Requiring extra protection to

prevent battery damage and thermal runaway

Flexible batteries are not widely used in the

automotive market, but we are not unfamiliar with it. Basically, our mobile

phones all adopt “flexible batteries”, but in 3C digital products, we do not

call it flexible battery, but polymer battery. The advantages and disadvantages

of flexible battery almost coexist with each other, because the shape of

flexible battery is flexibly designed (customized according to customer needs,

and the battery cell is also re-manufactured), so the number of existing flexible

batteries of the same model is too small. In addition, the cost of developing a

new set of flexible battery pack is also quite high.

Email :tob.amy@tobmachine.com

Skype :amywangbest86

Whatsapp/Phone number :+86 181 2071 5609