The cathode materials of lithium batteries are lithium cobalt oxide LiCoO2, ternary material NiMnCo, lithium manganese oxide LiMn2O4, and add conductive agent and binder, and coated on aluminum foil to form a cathode electrode. The anode electrode is coated with layered graphite plus conductive agent and binder on the copper foil, the more advanced anode layered graphite particles have adopted nano-carbon.

1. Slurry mixing: Use a special solvent and a binder to mix with the powdered cathode or anode active materials, and mix them evenly to make a slurry of cathode or anode materials.

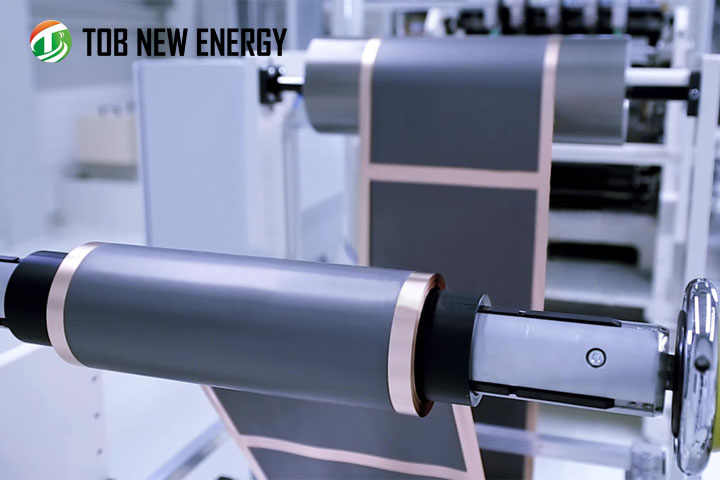

2. Coating: The cathode or anode electrode slurry is uniformly coated on the surface of the metal foil by an automatic coating machine, and the cathode or anode electrodes are automatically cut into cathode or anode electrode sheet after automatic drying.

3. Assembly: According to the top-down sequence of cathode electrode sheet-separator-anode electrode sheet-separator, the electrolyte is injected, sealed, and the cathode or anode tabs are welded to complete the assembly process of the battery to make a finished battery.

4. Formation: put the finished battery in the tester for charge and discharge test, screen out the qualified finished battery.

TOB NEW ENERGY LIMTED can supply full set of lithium battery equipment and materials, if you are interested in it, please feel free to contact us, looking forward to discuss with you.

Thank you for reading!

Contact person:Gavin Zhu (Engineer & Sales)

Email:tob.gavin@tobmachine.com

Skype: tob.gavin@tobmachine.com

Wechat: TOB-007

Previous :

Transportation of Equipment and MaterialsNext :

Swagelok cell and split test cell