Areal density(mg/cm2):Areal density refers to the mass per unit area, which in this case is (the mass per unit area ofthe region ignoring the volume).

Compacted density(g/cm3):The compacted density indicates the mass contained in a unit volume, which has a lot to do with the properties of the material itself.

Thickness:The total thickness of the material and the foil is generally expressed in microns (μm).

Areal density(g/cm3)= Compacted density(mg/cm2)/ Thickness(μm)

Key points of lithium-ion battery areal density design:

Generally, when designing a battery, the capacity is determined. At this time, the number of layers and areal density are determined based on the gram capacity of the material and the proportion of active substances.

For example, if we determine that the bifacial density of a battery is 30 mg/cm2 and the compaction density is 2.5 g/cm3, we can calculate its thickness.

Thickness = Areal density / Compacted density =30mg.cm2 /2.5 g.cm3=120 μm (without foil thickness)

The unit of areal density is (mg/cm2). The higher the areal density, the more active materials it occupies on the same area of the electrode, and the higher the energy density of the battery cell.

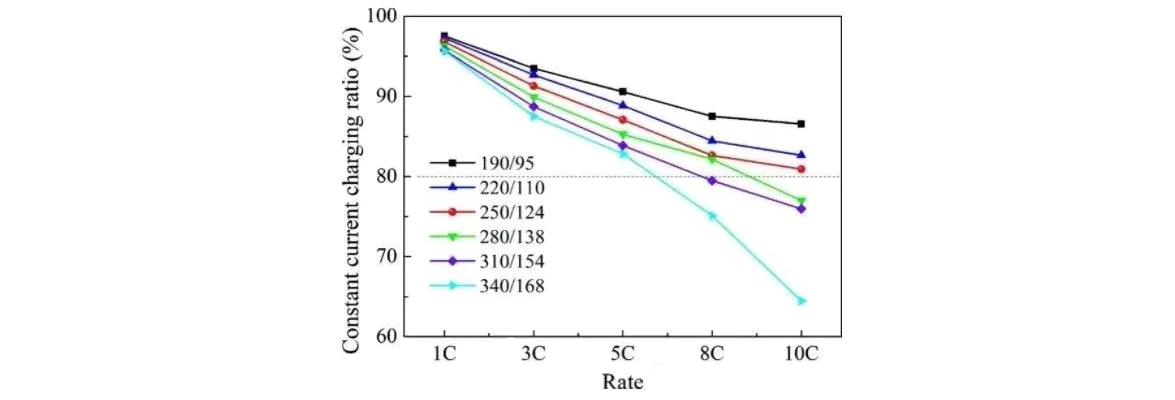

Reducing the areal density is the most effective way to design high-rate batteries, and increasing the areal density is the most effective way to design high-energy batteries. The smaller the areal density of the electrode, the thinner the thickness, which can directly reduce the diffusion distance of Li+, and the damage to the material structure caused by the cyclic insertion and extraction of lithium ions is also smaller.

Figure 1- Fast charging performance of LCO batteries at different areal density

Theoretically, the smaller the areal density, the more beneficial it is to improve the rate performance. However, the areal density design also has a lower limit, because when the areal density is small to a certain value, the large particles in the slurry cannot pass through the die of the coating machine, resulting in particle scratches, which will also have a negative impact on the battery.

In addition, batteries not only have rate requirements, but also capacity requirements. Simply reducing the areal density will inevitably increase the number of electrode layers, and the increase in the number of layers also increases the risk. For some 3C cells, the areal density is generally reduced to improve the battery's rate performance. For energy storage batteries, many will choose to increase the areal density and increase the energy density of the battery cell.